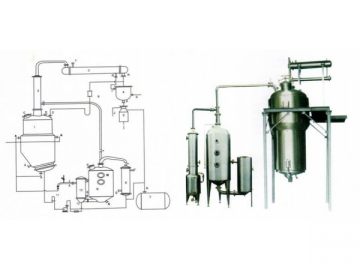

Hot Reflux Extracting and Concentrating Unit

Description:

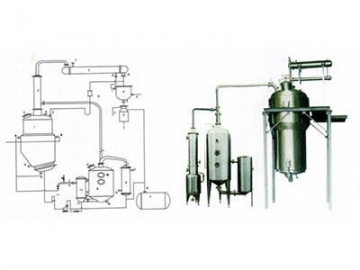

The hot reflux multi-function extraction and concentration unit is a kind of new product developed and manufactured by our company integrating the advantages of domestic similar equipment. By adopting the extracting and concentrating technique of extraction tank in combination with extrinsic cycle concentrator, it improves output rate of finished product, reduces solvent consumption, and greatly saves energy. It is a ideal kind of equipment for extraction and enrichment of traditional Chinese medicine and other materials.

Usage:

This equipment is suitable for the extraction, concentration, and percolation of heat sensitive materials in plant material, animals, traditional Chinese medicine, food additives and etc., and volatile oil extraction and alcohol recovery. It integrates the traditional process of “first extraction then concentration” into one same unit, and the extraction and concentration can be done synchronously. The unit can realize many kinds of extraction process requirements such as negative pressure, normal pressure, positive pressure, etc., and is also suitable for water extraction or alcohol extraction.

Work Principle:

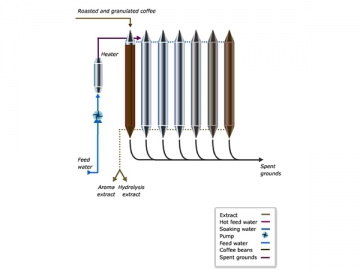

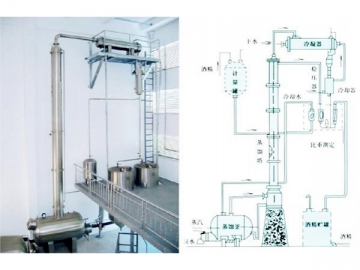

The Chinese medicinal materials (or other material to be extracted), which is chopped (or crushed) prepared and mixed properly according to the prescription, is put into the extraction tank. At one-time add the solvent in 5-10 times of the weight of medicinal material, soak for certain time (solvent species, adding amount and soaking time according to process requirements). Open the steam valve for heating, after about 1 hour cooking, from the bottom of the extracting tank the extracted liquid at a bit higher temperature continuously passes through a coarse strainer filter and the duplex filter for secondary filtration (other filtration mode can be selected in accordance with the different requirements), then enters the concentrator. The steam generated during concentration is cooled to condensate through the condenser, which is stored in the liquid storing tank and is pumped back to the extraction tank through a circulating pump.

Steam generated in extraction tank flows into the heating chamber as concentrator’s heating source, which will conduct heat exchange with medicinal liquid. The condensate in the heating chamber is converged into the liquid storage tank, and the residual vapor is cooled to condensate through the condenser, and is stored in the liquid storage tank. The recovered solvent flow through the medicinal material layers from the top to the bottom of the extraction tank, dissolving the solute in the medicinal material. Then the recovered solvent is pumped into the concentrator in recycle to repeat the process until the required concentrate density is achieved.

The extracted liquid is not stored in the extraction tank but directly flows into the concentrator. The temperature of the medicinal liquid is equal to that of the extracting tank, and the heat energy needed to heat the liquid medicine is saved. The secondary steam generated during the extraction process is fully utilized again in the process of concentration. All the vapor generated by the solvent is changed to condensate through heat exchange,and return to the extraction tank, therefore, the unit has quite excellent performances in energy-saving and solvent-balancing.

For detailed technical parameters for this series of product, pls refer to attachment herebelow.