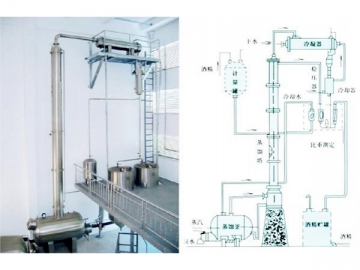

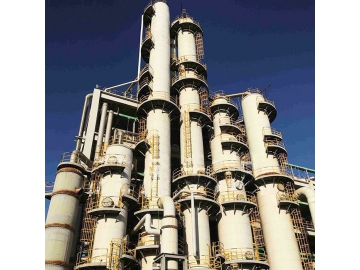

Alcohol Distillation Unit (Tower)

Application Scope:

The design can be suitable to reclaim ethanol in processing Chinese traditional medicines, Western medicines, dextrose, amylum, liquid oral drug, chemical, foodstuff, MSG, milk products and so on. It is also can be used for concentrating little batch and various thermal- sensitive materials under low temperature vacuum conditions.

Features:

1. Ethanol reclamation: The technology process has been improved after adopting the scientific vacuum operating technology and the capacity of reclamation also has been increased. Compared with the congenerous old-type equipment, the productivity has been expanded by 5-10 times and the energy consumption reduced by 30%. It is a energy-saving equipment with little investment in it and high reclamation efficiency.

2. Liquid material concentration: This design adopts the technology of outer heating with natural circulation and vacuum negative pressure evaporating to speed up the evaporating process and increase the concentration ratio, which can reach 1.35. The liquid material will be concentrated foamlessly within the fully sealed tank, so the concentrated liquid medicine will not be polluted and its purity is high. It can be cleaned conveniently (just open the covers of the heater, you can do that). It can be easily operated and has a dapper body and beautiful appearance. The heater, evaporator and thermal insulation device are manufactured as a unit. All the parts directly contacting with the liquid materials are made of SUS304 stainless steel. So it can meet the standard of GMP.

| Model Specifiction | DT500 | DT1000 | DT1500 | DT2000 |

| Amount of evaporation(kg/h) | 500 | 1000 | 1500 | 2000 |

| Operating pressure(Mpa) | 0.05-0.09 | |||

| Degree of vacuum(Mpa) | 0.08 | |||

| Concentration ratio | 1.2-1.35 | |||

| Overall dimensions(m) | 3×1×3 | 4×1.2×4 | 5×1.3×4.5 | 6×2.35×5.5 |