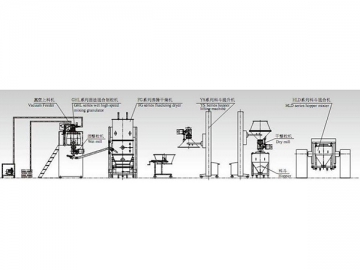

Dynamic Production Line for Extracting Chinese Traditional Medicine

Application Scope:

This product has been elaborately mended and improved on the basis of referring to the most advanced domestic products concerned at present. The design of the technology process, which can not only carry forward the traditional characteristics in the process of extracting Chinese traditional medicine but also can make the producing procedure successive , accords with the concrete situations of our country. The design is comparatively advanced and priced reasonably (only one tenth of the money invested in introducing the dynamic water extracting line) .It is especially suitable for the production in large, middle-sized or mini pharmaceutical factory and preparation room in hospital. This design should be applied and popularized for it is a ideal equipment to save energy. It is economical of electricity and water and also can shorten the time for extracting ,condensing and drying. Moreover, this product line can completely meet the standard of GMP.

The unit includes four main sections, as follows:

1. Extracting Device

It adopts dynamic warm-immerse extracting technology. The extracting tank adopts the technology of jacketed heating by steam with combination of a special agitator. The row medical materials are dynamically extracted under the temperature of 95℃±5℃ after been grinded and the extracting efficiency greatly exceeds that of the static extracting technology. So the row material and the energy will be saved and the extracting time be shortened.

2. Solid-Liquid Separating Device

This design adopts the technology of four-grade separation. It’s automatic residue filter, overflow type residue discharging centrifuge, vibrating sieve and tubular high-speed centrifuge play roles at the same time in the separation of liquid medicine and suspended solid. This design has it own incomparable advantages for it’s dryer residue, little remains of liquid medicine and little loss of liquid material compared with the same kind of domestic machine. It also can avoid the phenomena of coking, adhering to the wall and chocking which may arise in the process of evaporating concentration and spraying drying.

3. Energy Saving Triple-Effect Concentrating Device

This design has took all the elements into consideration, such as the quality of liquid material, the processing capacity of the machine, temperature index, concentrating ratio, the concentrating constant of the concentrated liquid, the phenomena of bubbling and scale building up which are common in processing Chinese traditional medicines and so on. It has a simple structure and can be conveniently loaded, discharged, cleaned and maintained. The triple-effect energy-saving concentrator has been reorganized after it adopted the pattern of vertically tubular type. The row material is fed into the single-effect inlet and then will change into ointment after passing through the double-effect and triple-effect device. The liquid medicine is automatically and continuously circulated. This design is featured of its high-speed, high using efficiency of energy, short evaporating and concentrating time, etc. compared with the single-effect device, the energy-saving efficiency of the triple-effect one can exceed 68%.

4. Spray Drying Device

This design is equipped with the new type high efficiency and high speed centrifugal dryer of which the operation is simple and constant, the automatic control can be easily carry out, the drying time is short, the motive power consumption is far little than that of the steam-driven one, the particle size of the product is uniform and the solubility and quality of the product is also good. This design paves a ideal road to reduce assistant material in the process of preparation of dissolved medicines and liquid oral drug and decrease the medical dosage. There are two models for choice in making up material: one is spray dryer and granulator united within one machine, the other is the spray dryer combined with a dry powder granulator.(the product line for liquid oral drug has no need to be combined with drying equipments)

| model parameters items | STQ-50G | STQ-100G | STQ-200G | STQ-300G |

| The extracting way and temperature | Water amount to be added(L/batch) | |||

| The processing amount for row material(kg/batch) | 50 | 100 | 200 | 300 |

| Water amount to be added(L/batch) | 500 | 1000 | 2000 | 3000 |

| Extracting time | 2 hours/batch , timing from the moment the extracting tank reaching the rated temperature | |||

| Means of solid-liquid separating | Centrifugal separation | |||

| Means of discharging the residue | Automatically scraping away | |||

| Means of concentrating | Triple-effect and energy-saving type continuously concentrating under vacuum conditions | |||

| Concentrating speed(kg/h) | 300 | 500 | 1000 | 1500 |

| Water evaporating capacity of the spray dryer(kg/h) | 30 | 60 | 120 | 180 |

| Water content ratio(%) | 3 | |||