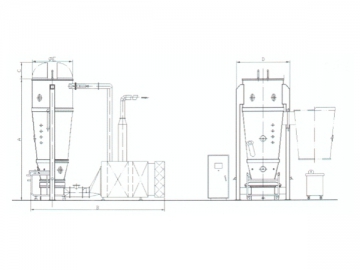

Multi-Function Fluid-Bed Granulator / Coater

Description:

Fluid bed coater is a new style granules and powder coating equipment that combines fluid bed spraying technology and coating technology well. Coating of bottom spraying, material flows in order, so we get uniform and continuous film.

Typical applications: pellets, granules, and powder coating, slow and control release coating, framework slow and control releasing capsule.

Lysine granulating and coating, omeprazole slow releasing coating, Chui Feng Tou Gu coating, Chinese Wolfberry moisture-proof coating and etc.

Features:

1. Coloring, taste masking odor, moisture-proof, anti-oxidation, water-proof, heat insulation, and separation coating for powder, granules and pellets.

2. Material dispersion is very good, and no adhesion problem;

3. Short distance of fog-drops to material, no spray drying problem. No coating material loss, and productive cost is low;

4. The design of cylinder for accelerator or cone for decelerator can be used for coating of fine fine granules, small particles,and coarse grains or particles and fine pellets.

Descriptions to Different Processes:

The series of product employes multiple processes of top spray for granulating, coating; bottom spray for coating, pilling and coating in a fluid bed. It is designed to meet every process requirements by changing the main parts (material container, trolley and sprayer etc.) on the main machine for the same equipment. It is also possible for a machine to contain only one kind of spray process. The machine is suitable for granulating, making pills and coating in Traditional Chinese Medicine, Western medicine, food-stuff, and chemical industry. Each kind of technique has different application range. Meet the requirement of “GMP” by working in a tightly closed clean container.

Top spray: it is widely used for drying, granulating, making instant granules, and costing; The granules are loose, instantly dissolved and the tablets are easily melt. There are common type and stirring type for top spray.

Bottom spray: it is used for coating fine granules and tablets. It is suitable for common film coating, sustained-release, Controlled release coating, enteric coating, fine particle coating.

Tangent spray: it is the one that has the widest application to make pills, granules coating, and covering. It is the ideal machine to make granules for capsules for the good roundness, density and smooth surface. High efficiency pellets can be produced by covering small pills using a solution or a powder.

Processes Technologies Application Cases for DLP Series Multi-Functional Granulation Coater:

1. Top spray (tangent spray) for TCM granules making, make pellets by tangent spray, coating (coloring) process technology application

Such as : XX Weitai capsule, Bushen capsule, Rehmannia XX pellets, Danggui Buxue capsule.

2. Make original pills/ blank core pills with tangent spray/ make pellets by coating powder/ coating (colored) process technology

Such as: Amphetamine sustained-release pellets, aspirin sustained-release pellets and sustained-release pellets of tetracyclin, quick release nifedipine pellets.

3. Make original pills/ blank core pills with tangent spray, make pellets by coating solution/ suspension/ coating (colored)

Such as: Cordyceps pellets, theophylline sustained-release pellets, indomethacin controlled-release pellets.

4. Make granules with top spray/ coating with bottom spray

Such as: Clarithromycin Granules, Thailand Miao Yin pigment granules.

5. Coating powder with bottom spray

Such as: Matrine powder, XX Medicine powder.

| Item | unit | DLB-3 | DLB-5 | DLB-10 | DLB-15 | DLB-20 | DLB-30 | DLB-40 | DLB-60 | DLB-80 | DLB-120 | DLB-150 | DLB-200 | |||||||||||

| top spray volume | 1 | 10 | 16 | 35 | 50 | 70 | 100 | 180 | 210 | 320 | 410 | 560 | 660 | |||||||||||

| bottom spray volume | ||||||||||||||||||||||||

| tangent spray volume | ||||||||||||||||||||||||

| top spray capacity | Kg/batch | 1.5~4.5 | 5 - 15 | 10-30 | 15-60 | 20-80 | 230-110 | 40 - 150 | 60-220 | 80 - 300 | 120-380 | 150-550 | 200-750 | |||||||||||

| bottom spray capacity | Kg/batch | 1.2-3.6 | 5 - 12 | 10-25 | 15-45 | 20-65 | 30-110 | 40 - 120 | 60-170 | 80 - 200 | 120-280 | 150-360 | 200-480 | |||||||||||

| tangent spray capacity | Kg/batch | 0.6-2.0 | 2.4 - 8 | 4-20 | 6--48 | 8-60 | 12-80 | 14- 100 | 20-120 | 24 - 150 | 40-200 | 60-280 | 100-360 | |||||||||||

| draft fan power | Kw | 3.0 | 4.0 | 4.5 | 5.5 | 7.5 | 7.5 | 15.0 | 15.0 | 16.5 | 35.5 | 42.5 | 55 | |||||||||||

| auxiliary fan power | Kw | 0.55 | 1.5 | 1.5 | 2.2 | |||||||||||||||||||

| electrical heater power | Kw | 7.5 | 9 | 15 | 21 | 26 | 30.5 | 35.5 | 45 | 51.5 | 70 | 100 | 145 | |||||||||||

| steam consumption | Kg/h | 40 | 65 | 70 | 80 | 90 | 160 | 185 | 210 | 280 | 320 | 350 | ||||||||||||

| steam pressure | MPa | 0.40 – 0.60 | ||||||||||||||||||||||

| compressed air consumption | M³/h | 0.25 | 0.35 | 0.7 | 0.6 | 0.9 | 0.85 | 1.1 | 1.3 | 1.5 | 1.8 | 2.0 | 2.2 | |||||||||||

| compressed air pressure | MPa | 0.40 – 0.60 | ||||||||||||||||||||||

| working temperature | ℃ | Room Temp.-120(automatically adjusted) | ||||||||||||||||||||||

| fed material temperature | ℃ | automatically adjusted | ||||||||||||||||||||||

| machine noise level | dB | |||||||||||||||||||||||

Note:

Generally, the equipment of Model DLB-120 and above specifications will be supplied independently with bottom spray and tangent spray.