Vibrating Fluid Bed Dryer

General Description:

This equipment is designed as a new type of drying equipment by adopting the principle of vibration fluidization. It has the advantages of high effect, energy-saving and good performance and etc. It is suitable for the drying, cooling and humidification in industries such as chemicals, pharmaceuticals, foodstuff, seeds, drink, mineral residue and etc.

This equipment is designed elaborately as a new product by our factory based on the national conditions. All the indexes gain the leading place among the similar products.

Features:

1. The fluidity is even and stable, and there are no phenomena of dead bed and the blowing through. Thus it can gain even products which is dried, cooled and humidified.

2. The vibration source is vibration motor, which runs stably, and is easy in maintenance, low in noises, long in service-life.

3. The adjustability is good. The material thickness, staying time for material in the machine and the amplitude can realize the stepless regulation in the designed scope.

4. It can be used widely, suitable for the materials with different specific gravity, grain size, moisture content.

5. The surface damage is small, so it can be used to dry fragile material. If the granules are not regular or uniform, the working effect will not be impacted.

6. The operation environment is clean, and can be operated continuously.

7. The heating pattern is direct. The thermal efficiency is high and the energy-saving effect is good. It can save the energy over 30% compared to the ordinary equipments.

Main Structure and Work Principle:

1. Main Structure

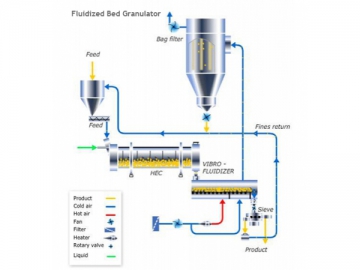

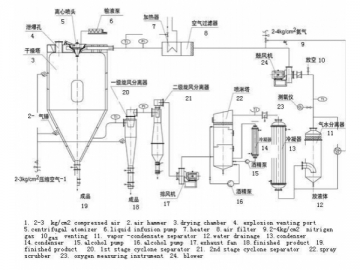

This series of drier main structure of all specifications are basically the same, which is divided into top cover, chamber, air inlet, sight-glass and pressure-measuring hole and etc. Ref. to the figure 1.

The spaces between the top cover and the fluid-bed forms the fluidization chamber for the material, and the damp air is draught out through the draught mouth. The holes for pressure-measuring and the temperature –measuring are used to measure the pressure and the temperature in the chamber. The operation condition can be monitored through the sight-glass.

The chamber is air-pumping room, and the hot air enters through the air inlet forming a certain pressure, so that the air on the fluid bed can be distributed evenly. The air temperature and pressure can be measured by the pressure sensor, which is mounted at the pressure-measuring hole. The material, which is dropped into the chamber by abnormal operation, can be discharged through the outlet for the accumulated material. For the details, please see to the sketch map for the structure.

2. Work Principle:

The equipment is driven by the vibration motor, and does a periodical vibration at a fixed frequency and a fixed direction. The treated material forms the fluidization status under the common action of excitement force and the mediums, so the material grains can contact with mediums adequately. Thus the heat transfer and the mass transfer are completed, gaining the objective of drying, cooling and humidification.

It is applicable for drying, cooling of powder or granule state materials, such as citric acid, monosodium glutamate, borax, ammonium sulphur, compound fertilizer, piece of radish, bean, lees, seed, mine reside and sugar, in chemical, pharmaceutical, foodstuff, grain, mine and so on industries.

For detaliled technical parameters for ZLG Series Vibration Fluid Bed Dryer, please refer to attachments herebelow.