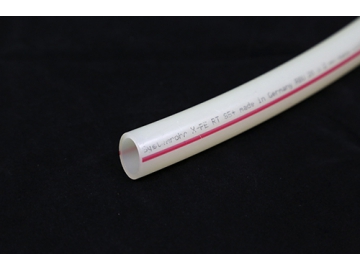

PEX-AL-PEX Pipe

The PEX-AL-PEX pipe is a composite pipe made of aluminum pipe, with the aluminum layer pressed between inner and outer layers of pipe. It combines the strength of a metal pipe with the durability of plastic. It can withstand temperatures up to as high as 95°C and a working pressure of 1.25MPa, thus meeting design requirements for high temperature radiation heating.

The PEX-AL-PEX pipe is widely used in drinking water systems, centralized water supply systems, radiator systems, heating systems, cooling systems and more.

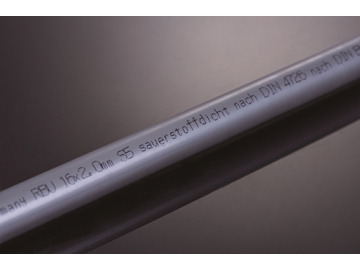

- Diameter: 3/8",1/2",5/8",3/4" and 1"

- Wall thickness: 2mm

- Material: PEX-AL-PEX, both the inner and outer layer cross-linked

- AL layer thickness: 0.2 mm

- Maximum working pressure: 10 bar (PN 10)

- Maximum operating temperature: 95°C

- The outer and inner layers of the PEX-AL-PEX pipe are made of PEX (silane crosslinking polyethylene)

- The intermediate aluminum layer reinforces the structure of the pipe, thus forming and retaining a particular pipe shape.

- It can withstand temperatures up to as high as 95°C and a working pressure of 1.25MPa, thus meeting design requirements for high temperature radiation heating.

- The PEX-AL-PEX tube has a large aluminum layer that allows it to bear high loads. It has all the characteristics of a metal pipe, making it safe and reliable.

- The thickness of the aluminum layer is evenly distributed, and the its stiffness is uniform. The hoop stress and shape change evenly, thus ensuring a reliable connection between the pipe and pipe fittings.

- The product features smooth end, uniform pipe wall and excellent roundness.

Step 1: Place the pipe cutter vertically on the pipe for a smooth, clean cutting. The cut pipe should be free of burrs.

Step 2: Select the appropriate reamer guide size and insert it completely into the PEX-AL-PEX pipe. The edge of the pipe must come into contact with the reamer blade. While holding the pipe, push the reamer in and rotate it in 2-3 circles (in any direction). If the chip is being cut, it indicates that the program is being correctly carried out.

Step 3: Slide the compression nut over the pipe and insert the main body of the PEX-AL-PEX compression joint completely into the pipe

Step 4: Slide the nut and O ring into the joint direction by hand, and then hand-tighten the compression nut (about 2 circles) on the joint. Place a hook wrench on the connector and place another wrench on the compression nut, and then tighten the compression nut (about 1-1.5 circles).

Step 5: The connection is completed and then check the fittings.