Stainless Steel Welded Pipe (High Frequency Induction Welding)

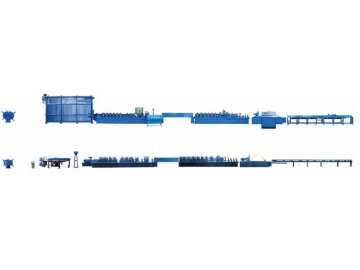

As a professional stainless steel pipe producer in China, we can provide customers with stainless steel welded pipes manufactured using high frequency induction welding technology.

Features

1. The high frequency induction welded pipe produced by KEYSWON is perfectly formed and has uniform wall thickness.

2. Our stainless steel welded pipes are usually produced with small diameters and thin wall thickness. Their diameters do not exceeding 610mm and wall thicknesses are within 12mm.

3. Highly automated production mode guarantees the uniformity of our welded stainless steel tubes.

4. The stainless steel welded pipes have no burrs and are inspected by NDT on line to guarantee the high quality of the welding seams.

5. Our high frequency induction welded stainless steel pipe is particularly suitable for constructing pipe truss structures.

Our stainless steel welded pipes come in straight pipe, U-shape pipe, square pipe, rectangular pipe, oval pipe, irregular pipe, cold drawn pipe, hot extruded pipe or pierced pipe.

Technical Parameters| Design and Manufacture Standard | ASTM/ASME, DIN, EN, JIS, GOST |

| Type/Shape | Straight, U-shape, square, rectangular, oval, irregular |

| Raw Material | 304/304L, 316/316L, 317/317L, UNS S31803, UNS S32205, T/P9, UNS N06625, Gr.1, Gr.2, Gr.3 |

| Manufacture Process | Cold drawing, hot extrusion, piercing, welding, straightening, hot bending, annealing, quenching, pickling, etc. |

| Test and Inspection | NDT, chemical analysis, hydrostatic test, mechanical property test, appearance and dimension inspection |

| Size NB/SCH Metric | OD: 51~219mm; WT: 6~32mm Cold Drawn pipe OD: 6~630mm; WT: 0.5~35mm Welded pipe OD: 6~3000mm; WT: 0.5~65mm |