Steel Wire Cord Calendering Line

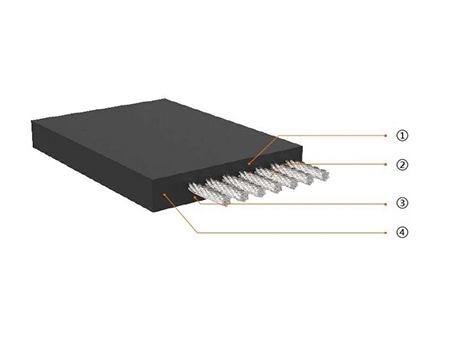

Steel Wire Cord

Application

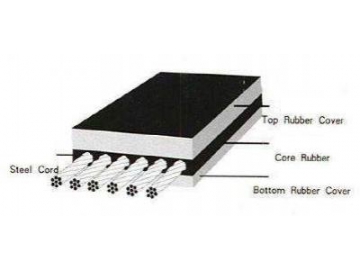

The steelwire cord calendering line is used for double-faceonce continuous coating rubber sheet on steel wire cord of tire body or beltlayer of meridian tire.

Features

1. Roll is made of chilled cast ironalloy, finishing machined surface, hard and wearable: with drilled holes onroll circumferential edge, using overheated water to heat, getting good heatingeffect.

2. The roll bearings of the steelwire cord calendering line are tailor-made double rowradial rolling bearings. The bearing body is made of cast iron, having goodshock absorption performance and enough strength.

3.

4.

5.

6. The wind-up is a double-stationcentering winder, including two separate winding setups and one working-stationoverturn mechanism. The whole winder has features of simple operation and lowlabor intensity.

7. The drive system uses a digitalspeed regulating device as driver; the entire machine uses PLC as controllerand provides fieldbus control technology.

8. Our company doesn’t supply steelwire spindle let-off device, it needs user’s preparation.

Application

The steelwire cord calendering line is used for double-faceonce continuous coating rubber sheet on steel wire cord of tire body or beltlayer of meridian tire.

Technical Specifications of the Steel Wire Cord CalenderingLine

| Model parameters | XYG-4S1000 | XYG-4S1300 | XYG-4S1500 |

| Roll number pcs | 4 | 4 | 4 |

| Arrangement form | S | S | S |

| Diameter mm | 450 | 550 | 610 |

| Length mm | 1000 | 1300 | 1500 |

| Roll linear speed mm | 4-40 | 4-40 | 4-40 |

| Speed ratio | 0.5-1 (Adjustable freely)

| 0.5-1 (Adjustable freely) | 0.5-1 (Adjustable freely) |

| Calendared product’s max. width mm | 800 | 1000 | 1300 |

| Thickness mm | 1.2-3 | 1.2-3.5 | 1.2-3.5 |

| Drive motor power kw | 4x45 | (2x55) (2x75) | 4x110 |

| Weight t | ~ 50 | ~ 68 | ~ 78 |

TechnicalParameters of the Steel Wire Cord

| Model parameters | XYG-F4S1000 | XYG-F4S1300 | XYG-F4S1500 |

| Double-station spindle number pcs | 700x2 | 700x2 | 900x2 |

| Max. winding d iameter of mess wire coiler mm | 400 | 400 | 400 |

| Max. tension kN | 1.5 | 1.5 | 1.5 |

| Max. splicing pressure kN | 65 | 65 | 65 |

| Heating plate size mm | 1000X180 | 1200X180 | 1500X200 |

| Max. heating temperature ℃ | 200 | 200 | 200 |

| Electric heating capacity kw | 6X2 | 6X2 | 9X2 |

| Reel quantity on coil-out stand pcs | 5 | 5 | 5 |

| Force measuring roll’s max. tension kN | 20 | 20 | 20 |

| Cooling roll size mm | 8- ¢ 600x1000 | 10- ¢ 600x1300 | 10- ¢ 600x1500 |

| Max. cord tension of cooling device kN | 20 | 20 | 20 |

| Max. accumulated fabric amount m | 40 | 40 | 40 |

| Max. cord tension of accumulation device kN | 1.5 | 3.0 | 5.0 |

| Centering device’s guide roll size mm | 2- ¢ 250x1000 | 2- ¢ 250x1300 | 2- ¢ 250x1500 |

| Cutting speed m/s | 0.42 | 0.42 | 0.42 |

| Max. winding diameter mm | 1100 | 1100 | 1100 |

| Max. width mm | 800 | 1000 | 1200 |

| Speed m/min | 4-65 | 4-65 | 4-65 |

| Power kw | 18.5 | 22 | 22 |

| Liner diameter (four-station let off) mm | 400 | 400 | 400 |

| Overall dimensions(LxWxH ) (excluding spindle room) | 17800x8500x5900 | 17800x8700x5900 | 18000x8500x5900 |

| Weight t | ~ 40 | ~ 46 | ~ 60 |

As a China-based steelwire cord calendering line manufacturer and supplier,we offer a wide variety of products that includes our hydraulic BOM tire press,two roll rubber mixing mill, rubber tire shredder, conveyor belt vulcanizingmachine, and many others.