Metal Cutting and Welding

Oxy-hydrogen machines have been used with billet cutting machines since the early 1960s, but in the last decade, we have further developed our oxy-hydrogen generators, carbon cleaning machines, oxy-hydrogen flame cutting machines, and oxy-hydrogen gas welding equipment to apply to other metal processing and heavy machinery in the chemical and petrochemical, aerospace, automobile and boiler, panel processing, patternmaking, and hydropower industries.

- Meets different flame requirements such as a neutral flame, carbonizing flame and oxidizing flame.

- Leaves cutting surface smooth and flat with no residue or dregs.

- Narrow cutting edge means the clean technology machine won't waste material, there's a smaller heat affected zone and no deformation.

- No hidden issues such as burning back, ensuring cutting safety.

- Minimal pollution makes it more environment friendly.

- Economically efficient, saving you 70-75% more than acetylene gas and 40% more than propane gas.

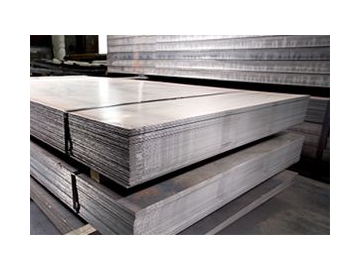

- Suitable for low, middle carbon steel and low-alloy steel with the thickness under 300mm.

- Compatible with manual, semi-automatic and automatic cutting machines.

Related products

Send Message

Most Recent

More

Other Products

Videos