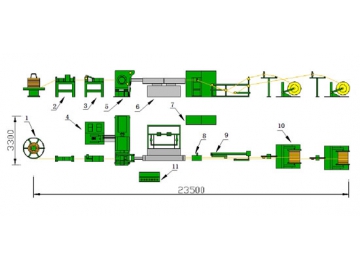

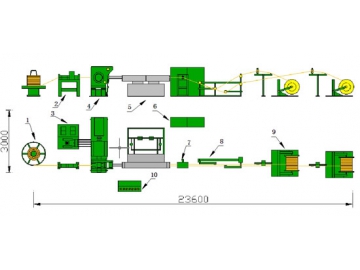

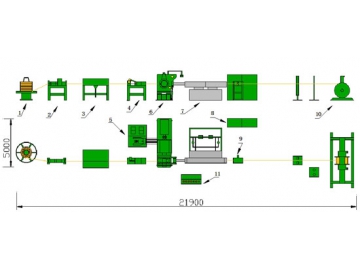

LFDT Rod Breakdown Machine for Copper Wires

Application

The non-sliding copper rod break down machine is used for drawing the Φ8mm copper rod into the Φ1.2 ~ Φ4.0mm copper wire. After drawing, the copper wire will directly, continuously go through the softening and annealing treatment. Then, it will be coiled by the coiling machine such as dual spooler or single-spooler.

Features

1. The well structured non-sliding copper rod break down machine is beautiful in appearance.

2. Diameter of its wire drawing drum is Φ450mm. The drums are independently driven by the AC variable frequency motor, and the speed can be synchronously adjusted for the instant die replacement.

3. This copper wire drawing machine applies the synchronous belt transmission. It is convenient to maintain.

4. Both programmable controller and touch screen are utilized to coordinate the working status of all the equipment parts. The parameters can be set, modified, and displayed via the touch screen.

Advantages

1. This non-sliding copper rod break down machine applies the quick mold change system which is driven by the fractional motor. The mold matching is convenient all the more.

2. Non-sliding wire drawing can prolong the service life of wheel rim and wire drawing die.

3. Thanks to the application of converter technique, this wire drawing bench is more efficient and energy-saving.

Product Improvement

1. With the real-time tension control system, the tensile force can be set and displayed via the operating screen.

2. The pneumatic type coiling method adapts to coiling the wire of different diameters.

Sales Case

The rod break down machine has been exported to Turkey,Egypt, Thailand, Iran, etc.

| Drawing capstan dia. (mm) | Quantity of wire | Drawing times | Applicable wire dia. (mm) | Dia. of finished product (mm) | Max. drawing speed (m/s) |

| 450 | 1 | 9 | 8.0 | 1.85-4.0 | 22 |

| 450 | 1 | 11 | 8.0 | 1.5-4.0 | 25 |

| 450 | 1 | 13 | 8.0 | 1.2-4.5 | 25 |

| 450 | 2 | 13 | 8.0 | 1.2-4.5 | 25 |