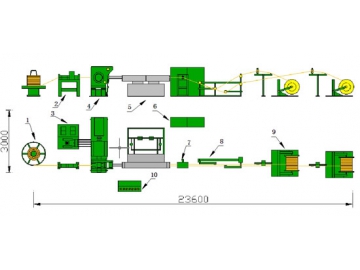

LHDT Rod Breakdown Machine for Copper Wires (Sliding Type)

Application

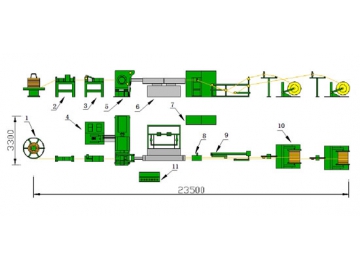

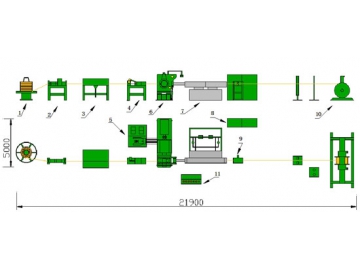

The sliding type copper rod breakdown machine is applicable for drawing Φ1.2 ~ Φ4.0mm copper wire from the Φ8mm copper rod. The copper wire after drawing will directly, continuously go through the softening and annealing treatment. Ultimately, it will be coiled by a dual spooler or single-spooler.

Features

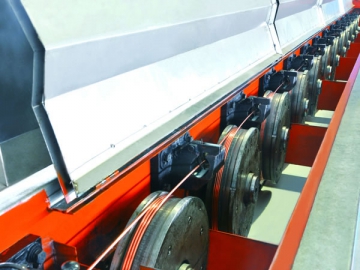

1. This sliding type copper rod breakdown machine is equipped with Φ450mm wire drawing drums, all of which arranged in a line.

2. Those constant-speed wheels and wire-drawing wheels are driven by different motors. But their speed can be synchronously adjusted. Consequently, the instant die replacement can be achieved.

3. With the programmable controller and touch screen, parts’ working status of this wire drawing machinery can be coordinately adjusted. A touch screen is used to display, set, and modify the parameters. The control system is reliable, and convenient to operate.

Improvement

1. A new type coiling system is applied to the sliding type copper rod breakdown machine. It not only improves the success rate of coiling, but also lowers the failure rate.

2. A pneumatic type coiling method is applied for coiling the wires of different diameters.

Advantages

1. Gear of this cable machinery is processed by grinding. It produces little noise.

2. The transmission box applies the one-piece casting, which puts an end to the oil leakage problem.

Sales Performance

This wire drawing equipment not only sells well in the domestic market, but also is highly welcomed in the overseas market. It has been purchased by the clients from Russia,Vietnam, Iran, India,Poland, etc.

| Drawing capstan dia. (mm) | Drawing times | Applicable wire dia. (mm) | Dia. of finished product (mm) | Max. drawing speed (m/s) |

| 450 | 9 | 8.0 | 1.85-4.0 | 18 |

| 450 | 11 | 8.0 | 1.5-4.0 | 22 |

| 450 | 13 | 8.0 | 1.2-4.5 | 25 |