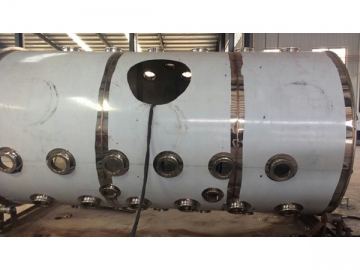

PVD Vacuum Coating Machine for Surgical Instruments

Vacuum coating provides a high resistance to corrosion, bright clean surface, and a strong mechanical bond. These properties make it ideal for coating surgical instruments that usually need to be built to high hygiene standards. BITE PVD coating system uses multiple cathodic arcs to ionize the target, creating high energy ions to sputter and react with the substrate until the desired coating thickness is achieved.

Features of Cathodic Arc Deposition

1. BITE vacuum coater can be re-configured to meet customer's specific application requirements. Thanks to continuous technology improvements, our vacuum coating machine can have more desirable features than previous models.

2. PVD coating system provides a strong mechanical bond, and the resulting coating layer does not easily peel or flake. It also enables a high ionization degree, fast deposition rate, and allows a wider choice of materials to be deposited.

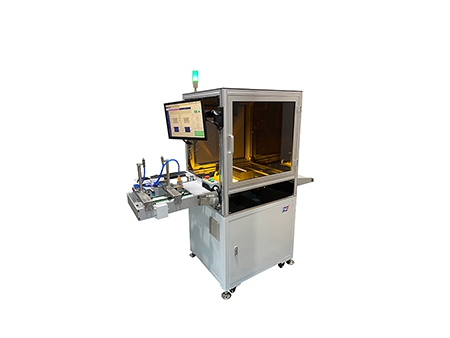

3. BITE PVD coating machines features a touch screen, PLC system, vacuum gauge, three flow controllers (that control 3 circuits of flow separately), one bias voltage power supply (with voltage converter), four cathodic arc power sources (with voltage converter), four side-mounted heating tubes, and a PID temperature controller.

Recommended Models