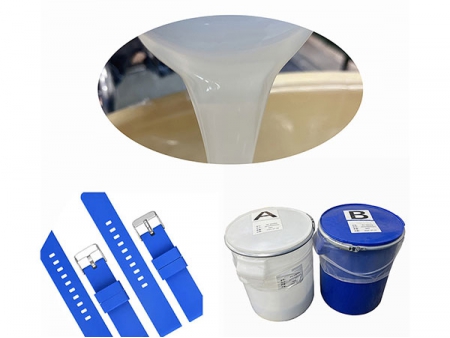

PVD Vacuum Coating Machine for Watch Straps and Watch Bands

The shiny chrome or brass plating on some watch cases and straps can be applied by vacuum coating, or physical vapor deposition to be precise. It is a thin film of metallic coating that has a high density with few visible pores, and does not flake, peel or wear off easily over time. Because the PVD coating system is able to produce a uniformly thin deposit, the result coating layer does not affect the dimensional accuracy of watch cases and straps, thereby still ensuring a tight fit with other parts of the watch.

Let's look at a few benefits below of the PVD coating system.

1. The PVD coating machine uses energized ions to sputter clean the substrate surface so that the substrate is readily receptive to subsequent deposit. Sputter cleaning also strengthens the mechanical bond between the coating and the substrate.

2. Sputter cleaning simplifies the substrate cleaning process before deposition even begins. Thanks to constant evolution that takes place due to technology improvement, coating service providers now can apply various metal and metal compound coatings to an item, including TiN, ZrO and ZrN. Better yet, PVD coating process can be completed in a short time and at an affordable cost, making it an ideal choice for metallic coating.

Recommended Models