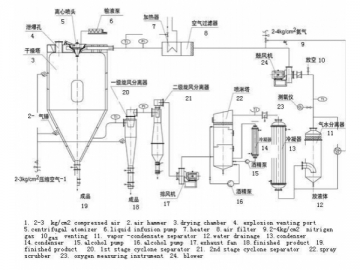

Horizontal Spray Dryer

In comparison with domestic large-size vertical drying equipments, our horizontal dryer based on foreign advanced technologies is more compact in structure,

smaller in floor area and easier for operation and maintenance. With advantages in energy saving, product quality and automation, it is an ideal upgrade of vertical drying equipments.

Product Quality:

For horizontal dryer, powders are centrally discharged, namely only one powder outlet is design to solve the problem of material accumulation in the pipeline, ensure the consistency of granularity and moisture content of powders and quality of product, improve the product condition, reduce the retention time of powders in the pipeline after drying and effectively protect the active ingredients of product. For vertical dryer, however, there are various powder outlets, and only the finest powder can reach the final bag type dust collector; therefore, the moisture content and granularity of product vary with powder outlets, materials may accumulate in the pipeline, the retention time after drying is long, both internal and external conditions of product are poor, and active ingredients are lost seriously.

Floor Area:

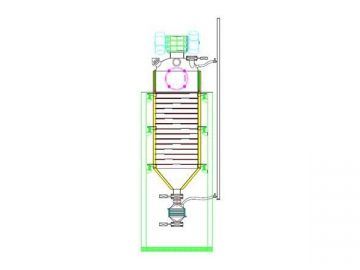

The horizontal dryer of compact structure and reasonablelayout can enable the processes of atomization of material, dewatering and drying with hot air, collection and delivery of powders, venting, dedusting and discharge of powders in the same cabinet, thus it has a small floor area and it is easy for operation and maintenance. For example, a 1300kg/h horizontal dryer is (L) 15m× (W) 8m× (H) 10m in size, while a vertical dryer of the same water evaporation, that adopts the design of vertical spraying downward to form droplets and uses air flow for delivery of powders as well as the separated cyclone separator and bag type dust connector, has a higher tower body and larger floor area.

Operation:

Horizontal dryer is easy for operation. It is highly automatedand has low failure rate and no dead angle. Only a high-pressure washer is required for internal cleaning and maintenance, and workers can stand and work easily,without any potential safety hazard. In the case of vertical dryer that is dozens of meters high above the floor, however, it is hard to clean thoroughly, there are dead corners, and operators need to work at heights during maintenance. It is obviously unsafe and difficult for operation.

Advantages of Horizontal Pressure Spray Dryer:

Horizontal pressure spray dryer is significantly superior to vertical dryer in use and energy consumption:

I. For vertical dryer that adopts the design of vertical spraying downward to form droplets and uses air flow for delivery of powders, the tower body is high, and the separated cyclone separator and bag type dust collector must be used; therefore, the floor area is large, and it requires for a high plant with large area; additionally, the moisture content and granularity of powders vary as there are multiple powder outlets and only the finest power can reach the final bag type dust collector!

For horizontal dryer that enables the processes of atomization of material, dewatering and drying, delivery of powders with low-speed circulating scraper, venting, dedusting with bag type dust collector and discharge of powders in the same compact drying cabinet, the floor area is small and the tower height is low. For example, the highest point of 1900kg/h horizontal dryer is 12m only. Additionally, it is safe and easy for internal cleaning.

II. Heat loss: As the processes of material atomization, dewatering, drying, powder delivery and dedusting are continuously completed in the same compact cabinet and the cabinet body, and even exhaust duct, is covered with a complete insulating layer (100mm thick), heat loss of horizontal dryer is reduced to the lowest. You will not feel hot when you touch the surface of the drying equipment by hand during operation!

III. Energy consumption: Horizontal dryer is designed with an exhaust gas heat recovery system, which can reduce energy consumption and improve the comprehensive heat utilization ratio of the drying equipment. According to our practical experiences over the years, for a vertical dryer without heat recovery system and subject to heavy radiation loss, the energy consumption is about 1300kcal per 1kg water evaporation. For a 1000kg/h drying equipment, the vertical dryer will consume 430,000kcal more heat per hour! This means 88kg more 5000kcal standard coal or 50.6m3 natural gas (calorific value 8500kcal/m3) is consumed in an hour.

This series of spray dryer is applied in foodstuff industries like animal blood product and other fields. Generally it has its own unique advantages in some certain aspects. Please refer to the aspects for your kind attetnion below.

Attentions before Order:

The space available at the user's site, especially the height;

Liquid name and property: solid contents(or water contents),viscosity,surface tension and PH value;

Dry powder density residual water contents allowed,particle size,and maximum temperature allowed.

Output: shift time daily;

Energy that can be available at user’s site: steam pressure, electricity properly,fuel of coal,oil and natural gas;

Control requirement: whether or not the inlet and outlet temperatures should be controlled. Whether the whole control system should be fully automatic or semi-automatic;

Powder collection requirement: whether it's necessary to use cloth bag filter and the requirement of the environment of the exhausted gas.

Other special requirements