Stainless Steel AP/EP/MP/BA Pipe

In addition to seamless stainless steel pipe and welded steel tube, we also provide value-added stainless steel AP/EP/MP/BA pipe. Our stainless steel pipe processing capability is proven to meet most demanding needs from all industrial sectors. Generally, we offer AP (Annealed and Pickled) pipe, MP (Mechanically Polished) pipe, BA (Bright Annealed) pipe and EP (Electropolished) pipe.

Classification

Precision stainless steel tube often occurs oxidation layer in colors of black or yellow during processing. AP pipe emerges as the ideal solution to this problem by utilization of pickling and passivation, thus further enhancing steel appearance and corrosion resistance.

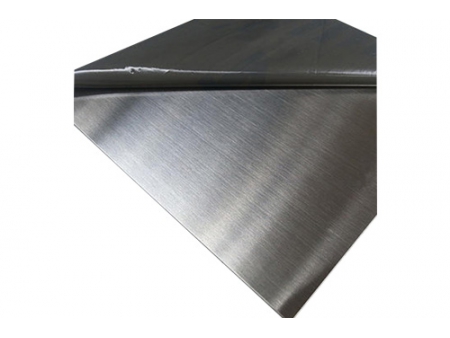

This precision metal pipe introduces machining approach to get rid of uneven surfaces. For more attractive appearance, we normally use wheel grinding or sandblasting.

Bright annealing is a part of stainless steel annealing process which is conducted in atmosphere of hydrogen protection or vacuum. The thermal process technology delivers resistance to oxidation and certain brightness to surface. Therefore, inner surface roughness is less than 0.4μm, and outer surface is less than 0.6μm.

This product is the time-verified pipe fitting for ultra-pure and special gas piping system. It also finds extensive applications in industries of photoelectricity, semi-conductor, solar chemical, medicine and food, etc. Furthermore, BA pipe is the base material for EP pipe.

EP pipe is derived from BA pipe through electrochemical polishing. We deploy the stainless steel into special chemical solution consisting of all kinds of elements, and utilize anodic dissolution under electropolishing condition to achieve smooth and bright surface. As a result, the inner surface roughness is increased to 0.2μm.