Pulp Moulding Machine, HX1000 Series

-

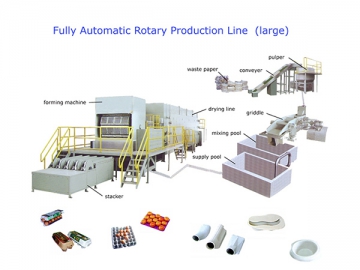

HX1000 Series Pulp Molding Machine -

Small Size Semi-auto Pulp Molding Machine

Features of the Pulp Molding Machine

1. The pulp egg tray molding system has only one face, one molding plate, and one transfer plate. Each plate can be provided with dies for an egg tray capacity of 30 eggs.

2. Thisegg tray machine is designed with a vacuum automatic drainage system and automatic die wash system. The pulp molder produces wet pulp egg trays in the first step. The trays will then automatically be delivered to the drying system. Dried products will be automatically stacked, packaged and put into storage.

3. The PLC control system ensures an easy, quick, and safe operation.

Raw Materials

Plant fibers are frequently used as the raw materials of egg trays. They come in six categories.

1. Wood of coniferous tree: larch, Korean pine, masson pine, pinus sylvestris

2. Wood of broad leaved tree: Poplar, birch, gum wood

3. Herbage: Reed, bamboo, straw, sorghum stalk, bagasse

4. Bast fiber: Flax, jute, ambary, mulberry bark, cotton stalk bark

5. Woolen fiber: Cotton, cotton linter, cotton rag

6. Wastepaper fiber: (according to Chinese custom)

1) First grade wastepaper: White Shavings, broke that has not been printed on

2) Second grade wastepaper: Printed old books, magazines, newspapers

3) Third grad wastepaper: All wastepaper, used paperboard, broken carton except for the first and second grade wastepaper

Samples

- Drying racks

- Samples