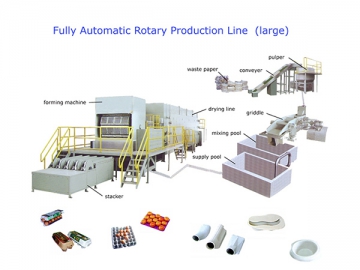

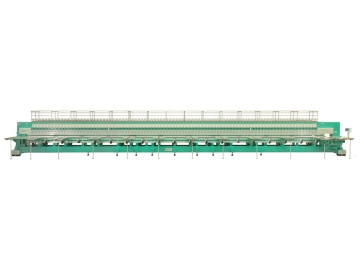

Pulp Moulding Machine, HX3000 Series

The pulp molding line comes with an octahedral rotary molding drum. Pulp suction pipes and air blow pipes on each of the eight faces that connect to the mold base and the molds, and also connect with the main pipeline through a valve mechanism. The forming mold and transfer mold base rotate driven by a variable speed motor and reducer, and the transfer mold drives the mechanical arm to implement a 90º reciprocating motion through the reducer.

Samples

Structure of the Pulp Molding Machine

1. Main Frame

An octahedral molding drum and mold base are engineered from high strength, corrosion, impact and mechanical fatigue resistant castings. This reduces the load on the transmission mechanism and extends the machine's service life.

2. Component Design

Key parts of the pulp molding machinery are all processed using a CNC machine, effectively improving the parts accuracy and tolerance clearance among them.

3. Valve Mechanism

The valve mechanism consists of the transmission case and the distribution case. They are improved from a one-piece structure to a standalone structure, effectively solving the problem of easily waterlogging the transmission case. In addition, the split structure is conducive to equipment maintenance.

Parts

- Compressor

- Fuel oil type drying line