Pulp Moulding Machine

We offer a full set of pulp molding machines in a variety of models, including single face, four face, eight face, and twelve face options. The pulp molder comes with two molding plates, of 8 faces and 12 faces, as well as one transfer plate. Each molding plate can be installed with 4 sets of egg tray molds, allowing for a capacity of 30 eggs. The machine can be equipped with a total of 52 molds. Along with the egg tray, this pulp molding equipment can be used to produce fruit trays and industrial trays.

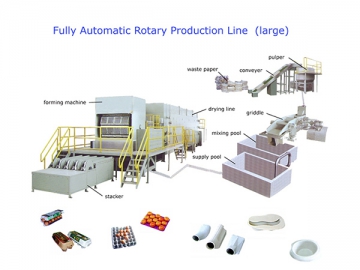

Process Flow

(1) Raw materials: virgin pulp or plant fiber

(2) Tap water

(3) Hydrapulper

(4) High consistency pulp chest

(5) High consistency pulp pump

(6) Sand and impurity removal system

(7) Waterproof agent, Oil-proof agent

(8) Pulp mixing chest

(9) Pulp storage chest

(10) Stock pump

(11) Circulation water tank

(12) High pulp chest

(13) Forming, qualitative, trimming

(14) Air compressor

(15) Water ring vacuum pump

(16) Finished product

(17) Test

(18) Counting

(19) Packaging

(20) Encasing

The production process of the pulp molding machine is comprised of 4 main parts: pulping, mixing, forming, drying, and hot pressing and shaping. Pulp with a certain consistency is mixed in a series of processes including disintegrating, screening, and water injection. The pulp will then be turned into wet blanks on special metal dies using vacuum absorption. The semi-finished products will undergo drying and hot pressing processes before being shaped into the final end product.

Features

1. Huaxia's pulp molding machine is designed with a mechanical and electrical combined control system, which allows it to carry out a continuous automatic production. The finished product comes with a uniform thickness and a high finish degree, making it suitable for the production of high grade paper trays.

2. The pulp machine uses an intelligent touch screen with a visible and user friendly operation interface. It has various functions, including fault display, fault alarm and remote control.

3. With the use of a PLC control system, the pulp molding machine has a stable performance and high control accuracy.

4. Parameters include product thickness, wetness and dryness, molding and shaping time, and the temperature can be set in advance.

5. The drying system is available in one layer, four layer or six layer drying chain boards. It uses a French or Italian burner, which is fueled using LPG, gas, or diesel. The drying system is equipped with an automatic control cabinet.

6. A reasonable structural design and exquisite mold processing technology ensures an efficient production of high quality pulp molded products. Huaxia has developed more than 1,000 different molds for pulp molding industrial packages and tableware involving household appliances, mobile phones, computers, ceramics, tools, light fixtures, crafts, health care products and agricultural products.

Pulp Molded Tray Types

Our pulp molding machine can produce a vast variety of trays:

1. Egg: Chicken egg trays, duck egg trays, quail egg trays, ostrich egg trays and gift boxes for various trays.

Specifications: 6 eggs (cover available), 8 eggs (cover available), 10 eggs (cover available), 12 eggs, 20 eggs, 25 eggs, 30 eggs, 42 eggs, 45 eggs.

2. Fruit: Apple trays, pear trays, kiwi berry trays, mango trays, persimmon trays

3. Industry: Mobile phone trays, electronic part trays, wine trays, medicine trays, shoe trays, solar tube trays, medical sanitary ware (disposable urinal and bed pan) and all kinds of industrial inner packages.

4. Decoration: 3D wall paper, large size stereograph

5. Agriculture: Rice seedlings cultivating bowls, watermelon seedlings cultivating trays, flower pots

6. Others: Gold bars, livestock, television, buildings, cars, decorative crafts, and targets for military training

We also offer pulp molding machines for various trays as per customer requests.