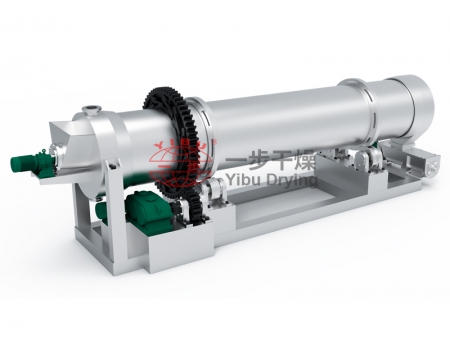

Drum Dryer (with Scraper)

Description:

The drum dryer with scraper is a kind of heat conduction type continuous drier .rotation for drying equipment. With the rotation of the drum, a certain thickness of material membrane is adhered to the drum surface through the lower part of the chute. Heat is transferred to the internal wall of drum, and then conducted to the outer wall of drum, further conducted to material membrane. Thus the material moisture is evaporated, dehydrated, and the wet material is dried. The dried products are then scraped off by the scraping blade fitted on the surface of the drum / cylinder, and fall down to the spiral conveyor under the blade, and are conveyed , collected and packed.

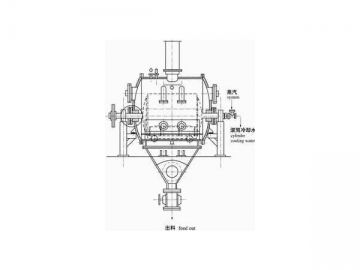

Working Principles of Drum Scraper Dryer:

Drum dryer is a kind of continuous drying equipment through steam jacket-ed heating. The rotating cylinder body is attached to a certain thickness of the liquid raw material film through the material tank set in the lower part. The sensible heat (Steam) is passed through the tubes to the inner and outer wall of the drum bodies, and then is conducted to the liquid raw material film, so that the moisture content of the raw material is rapidly evaporated and the paste reaction occurs. With the continuous rotation of the drum bodies, finally material is completely dried and the pasting process accomplishes.

The completely dried products are scraped off the rotating cylinder body by the scrapers installed in the surfaces of drums body, and then gathered in the screw conveyor at the bottom of the scrapers. At the discharge end of screw conveyor, a crushing device is set. After being crushed and flake products is to conveyed to the clean room for weighing and packing. At this point, the drying and pasting process accomplishes.

Features:

1. High thermal efficiency. The principle of heat transfer of the cylinder dryer is heat conduction whose conducting directing keeps identical in whole operation circle. Except heat dissipation of end cover and radiation loss, all heat can be used for evaporation of wet materials on the wall of the cylinder. Thermal efficiency can reach 80%-90%.

2. Large operation elasticity and wide application. Various drying factors of the cylinder dryer can be adjusted, such as density of feeding materials/thickness of material film, temperature of heating medium, rotating speed of the cylinder etc.. Which can change drying speed of the cylinder dryer. As these factors have no interrelation each other, it brings about great convenience to dry operation, and makes it applicable to drying of various materials and to meet different requirement of production.

3. Short drying period. The drying period of materials is normally 10 to 15 second, so it is suitable for heat-sensitive materials. It can be also operated under less pressure condition if it is put in vacuum.

4. Fast drying rate. As film of materials coated on the wall of the cylinder is very thin. Normally, thickness is 0.3 to 1.5mm,plus directions of heat and mass transmitting are identical, the evaporation strength on the surface of the film can keep at 30-70kg.H2o/m2

Range of Application:

It is suitable for drying liquid raw materials or thick liquid in chemical industry,dyestuff industry,pharmaceutical industry,foodstuff industry,metallurgy industry and so on.

Sketch of Drum Dryer Structure:

From its feature, it can be divided into two types: single cylinder and double-cylinder. Otherwise it can also be divided into two types according to the operation pressure: normal pressure and decompression type.

| Model & Size | Sizes of Cylinder mm Diameter×Length | Effective Heating Area M2 | Drying capacity Kg.H2o/m2.b | Steam Consumption kg/h | Motor Power kw | Sizes of Cylinder mm Diameter×Length | Weight kg | ||||

| TG-600 | φ600×800 | 1.12 | 40-70 | 100-175 | 1.1 | 1700×800×1500 | 850 | ||||

| TG-700 | φ700×1000 | 1.65 | 60-90 | 150-225 | 2.05 | 2100×1000×1800 | 1210 | ||||

| TG-800 | φ800×1200 | 2.26 | 90-130 | 225-325 | 3.75 | 2500×1100×1980 | 1700 | ||||

| TG-1000 | φ1000×1400 | 3.30 | 130-190 | 325-475 | 4.75 | 2700×1300×2250 | 2100 | ||||

| TG-1200 | φ1200×1500 | 4.24 | 160-250 | 400-625 | 4.75 | 2800×1500×2450 | 2650 | ||||

| TG-1400 | φ1400×1600 | 5.28 | 210-310 | 525-775 | 6.25 | 3150×1700×2800 | 3220 | ||||

| TG-1600 | φ1600×1800 | 6.79 | 270-400 | 675-1000 | 6.25 | 3350×1900×3150 | 4350 | ||||

| TG-1800 | φ1800×2000 | 8.48 | 330-500 | 825-1250 | 8.6 | 3600×2050×3500 | 5100 | ||||

| TG-1800A | φ1800×2500 | 10.60 | 420-630 | 1050-1575 | 8.6 | 4100×2050×3500 | 6150 | ||||

Notes:

Our company produces two categories of drum scraper dryer: single cylinder and double cylinder type. We can also design double-cylinder dryer with upper material feeder in terms of request from customer.