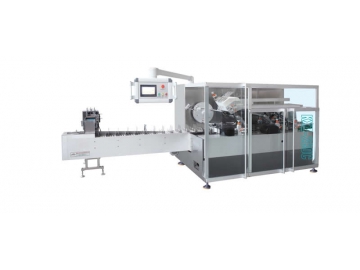

High Speed Shrink Wrap Bundler

Introduction

The KXG-590 high speed shrink wrap bundler is designed to package products in a variety of shapes, from food, to cosmetics, and everything in between. The heat shrink film materials include PVC, POF, and PE for customers to choose from.

Depending on the product to be packed, customers can determine if an automatic feeding system designed for production lines and large scale production is a necessary piece of equipment. Thanks to continuous operation and an enclosed packaging process, the shrink wrap bundler is efficient, and offers a great appearance to the final packed product.

Parameters| Maximum film width | 590mm | ||

| Product size | Strap length | L: 180mm-530mm | |

| case width | B: 30mm-200mm | ||

| case height | H: 50mm-130mm | ||

| Speed | 30-150 case/min | ||

| Type | PVC, POF, PE heat shrink film | ||

| Rated power | 3.6KW+16.5KW | ||

| Power supply | Electric motor 220V, 50HZ Heat wind recycling device 380V 50HZ | ||

| Type | Machine | Shrink tunnel | |

| Dimension | 7500 X 965 X 1750mm | 7500 X 1105 X 1750mm | |

| Shrink tunnel size | 2400 X 600 X 1700mm | 2400 X 600 X 1700mm | |

| Machine weight | 1000KG | 600KG | |

- The high speed shrink wrap bundler features a simple operation and reasonable design.

- It features a high speed horizontal sealing and cutting device,which ensures steady sealing and reduces the risk of torn products.

- Our machine comes equipped with a residual film collection device to save costs and help protect the environment.

- The wrapper features an orientation system where the orienting head grips products, and stops them in predetermined positions, which reduces the risk of film sticking to the blade, thus reducing film waste.

- The machine's display screen will show real time speed, output and product length.

- The PLC controller reduces the risk of circuit malfunctions, ensuring a steady machine operation.

- The wrapper features a simple, frequency conversion operation.

Related products

Send Message

Most Recent

More

Other Products

Videos