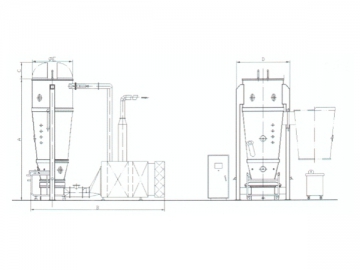

Fluidized Bed Jet Mill

Principle and Features:

When the compressed gas enters into the milling chamber, there are 4 crushing nozzles at the periphery of the milling chamber. The material is impacted by the jet stream at a high speed, and meanwhile the material mutual ly collides, so that the material is milled. The grading wheel separates the fine particles, and the coarse particles return to the milling chamber for milling in recycle The product collected from the discharge outlet of the grading wheel will be superfine powder with a uniform size distribution.

1. Apply to dry ultra technology. Air impact speeds can reach up to above 2.5 Mach, under normal circumstances it is very easy to obtain the particle ranging from 1 to 10 microns (μm). According to the nature of the material, particles less than 1 micron can also be obtained.

2. Due to the internal Grading wheel structure in the mill, coarse particles in product can be continuously milled in the cycle, and therefore products with uniform particle size distribution and a narrow size distribution range can be achieved.

3. The equipment has the advantages of short milling time, simple structure, convenient operation and maintenance, small floor area, low noise (72 dB) and no vibration and etc..

4. This mill has a higher average efficiency per hour, and it can carry out continuous grinding, which can maintain the purity of the products.

Scope of Application:

Minerals: kaolinite, mica, graphite, barite, quartz, zircon sand, calcium carbonate, talc and so on.

Chemical industry: three, three and two antimony molybdenum sulfide oxidation, titanium dioxide, alumina, dyes, pigments, such as carbon black.

Electronics: barium titanate, chromium oxide etc.;

Medicine: bismuth nitrate, cortisone, penicillin, pollen, pearl powder, nimodipine etc.;

Pesticide: carbendazim, thiophanate methyl, weeding, insecticidal powder powder and wettable powder.

| Specs. & parameters | 100 | 300 | 400 | 600 | 1000 |

| Working medium | Compressed air | ||||

| Equipped air amount M3/min | 3 | 6 | 10 | 20 | 40 |

| Working pressure Mpa | 0.7~1 | 0.7~1 | 0.7~1 | 0.7~1 | 0.7~1 |

| Feed sizes (mesh) | ≥60 | ≥60 | ≥60 | ≥60 | ≥60 |

| Milling Fineness(μm) | 1~200 | 1~200 | 1~200 | 1~200 | 1~200 |

| Treatment amount Kg/h | 3~30 | 15~100 | 20~150 | 100~450 | 200~1000 |

| Total equipped power Kw | 22~25 | 45~60 | 75~90 | 160~180 | 320~350 |

| Pesticide (400 mesh) treatment amount Kg/h | 10~30 | 100~200 | 250~450 | 400~800 | 800~1500 |

Note: If the other material is to be crushed, the parameters in the table are changed.