Acetaldehyde Plant

Request a Quote

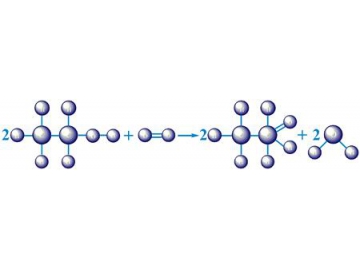

Acetaldehyde production includes 3 primary process: acetylene hydration, ethylene oxidation, and alcohol oxidation. Helipont currently utilizes the alcohol oxidation process for the production acetaldehyde, because alcohol features a low costs and a wide usage range. It also features a low conversion rate. We use double towers for absorption- one tower for circulation absorption, and the other for a spraying absorption and recycling plant in order to obtain the best consumption.

Flow chart

Main Equipment for Acetaldehyde Plant

- Evaporator

- Oxidation tower

- Absorption tower

- Mix the alcohol material.

- After removing impurities such as dust via air filter, the outside air enters the evaporator via the roots blower.

- Mixed alcohol and air react in the evaporator and generate acetaldehyde.

- Cool down the acetaldehyde and unreacted alcohol.

- Rectify the acetaldehyde.

Annotation: for more information, please do not hesitate to contact us.

Performance| Name | Specification and Composition | Consumption quota |

| Alcohol | ≥95% | 1.170t/t |

| Name | Specification and Composition | 4.3t/t |

| Process Water | 25PPM(5℃)Chloridion | 6t/t |

| Steam | 0.8MPa(Gauge) | 3.0t/t |

| Instrument Compressed Gas | 0.6MPa(Gauge) | 7m3/t |

| Circulating Cooling Water | Water Inlet30℃, Water Outlet38℃, Water Pressure 0.35MPa | 410t/t |

| Chilled Water | Water Inlet7℃, Water Outlet12℃ | 160×104KJ/t |

| Electric | 380V 50Hz | 250KWH/t |

| Waste Water | Ethanol 0.03%, Acidity 0.25%, COD5000ppm, BOD2000ppm | 5t/t |

| Exhaust Gas | Acetaldehyde≤0.1%, CO+CO2 ≤0.8%, H2+ CH4 ≤1.2%, H2O≤1%, N2≥96% | 1.143t/t |

| Acetaldehyde Yield | 99.7%wt |