Mobile Disc Vacuum Filter

Application

Our PBF series of continuous horizontal belt filters use a vacuum to clean and dehydrate the slurry, making them suitable for a variety of solid/liquid material separation applications. The vacuum filter is widely used in citric acid productions, phosphoric acid productions, fine chemicals industries, dyeing intermediates industries, beneficiation, metallurgy, paper industries, food industries, pharmaceutical industries, environmental protection fields and other fields.

| Slurry type | Flocculent addition Ratio to SS % | Filter cake moisture content % | Filtration efficiency kg/m.h | Slurry type | Flocculent addition Ratio to SS % | Filter cake moisture content % | Filtration efficiency kg/m.h | ||

| Industrial slurry | Paper mill sludge | 0.2-0.3 | 62-68 | 150-300 | Urban sludge | Raw sludge | 0.4-0.9 | 71-75 | 140-390 |

| Food industry wastewater | 0.6-1.0 | 75-80 | 60-120 | Digestive sludge | 0.2-2.7 | 65-75 | 140-390 | ||

| Textile factory wastewater | 0.7-1.1 | 60-65 | 120-300 | Activated sludge | 0.6-1.1 | 81-84 | 80-120 | ||

| Coal washing plant wastewater | 0.025-0.035 | 22-27 | 4000-5000 | Metallurgical wastewater | 0.013-0.02 | 25-35 | 1000-2000 | ||

Design Details

The filter presses we produce are an intermittent solid-liquid separation equipment. The filter press is composed of the filter plates and filter chambers, which are built with filter frame plates in a board or box arrangement. Under the pressure of the feed pump, materials fed into the filter chamber and pass through the filter medium, thus separating the solid and liquids. We have a filtration area ranging from 10M2 to 500M2, and compression methods that include manual compression, mechanical compression, hydraulic compression and automatic strength packing for customers to choose from.

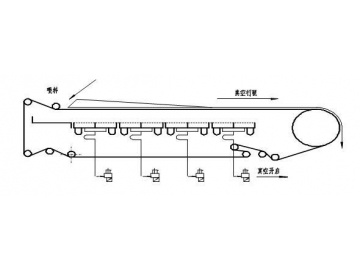

Vacuum part diagram

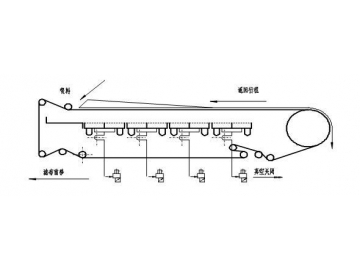

Vacuum part diagram Discharging part diagram

Discharging part diagram

Features

(1) Our product is light weight with a compact structure, and weighs as much as 20 to 30% less than other similar products available on the market today.

(2) The synchronous operation of the filter plate and filter belt is ensured with an error less than 2mm.

(3) The quick returning of the filter disc allows for a longer effective operating time.

(4) An advanced frequency converter is used in the control system. The vacuum filter plate runs at both low and high speeds, and will adapt to various filtration process requirements. Our system is stable, reliable, easy to maintain and has a long service life.

Design Details

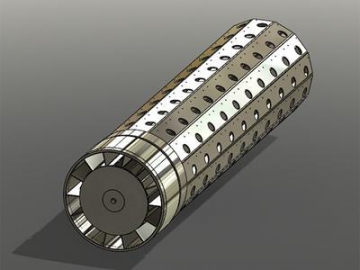

Our PBF series of continuous horizontal belt filter uses a vacuum to clean and dehydrate the slurry. We use a filter cloth as the filter medium, and the vacuum chamber is formed using a filter belt supported by a mobile disc. Solid/liquid materials are horizontally distributed along the filter medium, and gravity or vacuum suction is used to perform separation. The feeding, vacuum dehydration, cake washing, slag removal and filter cloth cleaning process are all performed simultaneously, giving the filter its high dehydration ability and excellent filtration effect.

(1) Vacuum process

At the beginning of the filtration process, the slurry is evenly distributed on the filter belt. The filter disk and the filter belt move forward simultaneously, and the vacuum suction is performed on the slurry until the vacuum disk leaves the metal sensing device and releases the vacuum.

(2) Discharging process

The filter belt machine continues to move at the same speed. When the vacuum disk hits the contact limit device, the vacuum switching valve is actuated, and the filter disk immediately releases the vacuum. The vacuum filter disk then returns after 0.5 seconds. The cylinder then quickly returns to its original position as the filter disk returns. This cycle of vacuum filtration process is performed repeatedly until filtration is complete.

(3) Washing, blotting, and slagging process

After the vacuum filter process, to better remove the moisture from the filter cake, countercurrent washing is performed several times. This reduces the mother liquor content in the filter cake to as little as 0.1%.

After washing, the filter cake is sucked through the suction drying area. The content of the filter cake varies according to different materials. Then, the washed and dried filter cake is removed by its change of curvature at the head wheel and the stripping device removes the filter cake.

(4) Filter cloth cleaning

A high-pressure flushing device is provided to clean the filter belt after discharging the filter cake. This procedure prepares the belt for its next operation cycle, and ensures long term, stable and high quality equipment operation.

Customizing Notes

Please tell us about your treatment target, estimated throughput, moisture content and machine material requirements.

Huaneng Jinhao manufactures water treatment equipment and domestic sewage treatment plant to global markets, with decades of experience, we can fabricate any water treatment equipment and machinery like industrial water decanter, water filtration equipment, sludge separation equipment, and the auxiliaries of water treatment equipment.

Index

solid liquid separation, industrial sludge treatment, sewage treatment