Frame Filter Press

Application

Frame filter presses are most often used in industries that require the use of solid/liquid separation equipment. Not only is an outstanding separation process carried out, but the equipment is easily adaptable, and features a number of advantages for the separation of viscous material. Our frame filter press is widely used for sewage treatment solutions in a variety of industries, including chemicals, dyes, petroleum, ceramics, pharmaceuticals, sugar, food, starch, paint and metallurgy.

| Model | Filter area m2 | Number of filter plates | Volume L | Filter plate size mm | Outer frame size L × W × H mm | Weight Kg |

| 10 | 26 | 130 | 500×500 | 2440×880×1100 | 850 | |

| 10 | 16 | 100 | 630×630 | 2318×1030×1015 | 1500 | |

| 15 | 24 | 150 | 630×630 | 2637×1030×1015 | 1750 | |

| 20 | 32 | 200 | 630×630 | 2957×1030×1015 | 2000 | |

| 30 | 48 | 300 | 630×630 | 3597×1030×1015 | 2500 | |

| 20 | 20 | 320 | 800×800 | 2755×1210×1270 | 2600 | |

| 30 | 30 | 480 | 800×800 | 3355×1210×1270 | 2900 | |

| 40 | 40 | 640 | 800×800 | 3955×1210×1270 | 3200 | |

| 50 | 50 | 800 | 800×800 | 4555×1210×1270 | 3500 | |

| 60 | 60 | 960 | 800×800 | 5155×1210×1270 | 3800 | |

| 70 | 70 | 1120 | 800×800 | 5755×1210×1270 | 4100 | |

| 80 | 80 | 1280 | 800×800 | 6355×1210×1270 | 4400 |

Design Details

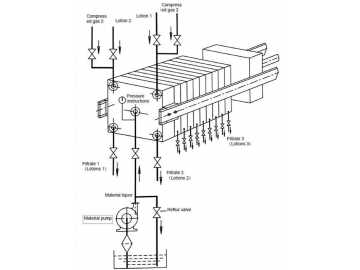

The filter presses we produce are an intermittent solid-liquid separation equipment. The filter press is composed of the filter plates and filter chambers, which are built with filter frame plates in a board or box arrangement. Under the pressure of the feed pump, materials fed into the filter chamber and pass through the filter medium, thus separating the solid and liquids. We have a filtration area ranging from 10M2 to 500M2, and compression methods that include manual compression, mechanical compression, hydraulic compression and automatic strength packing for customers to choose from.

The filter press is composed of a filter plate, a filter frame, filter cloth, and a pressing membrane. Both sides of the filter plate are covered with a filter cloth. When a pressing membrane is required, a filter plate is instead composed of a membrane and a side plate. Both sides of the membrane are coated with a rubber film, above which is the filter cloth, with side plates a common installation for filter plates.

When the filter cake needs to be dried, in addition to pressing with a membrane, air or steam is also compressed and passes through the washing port. The air stream can flush out the water in the filter cake to reduce its moisture content.

Features

• Low energy consumption and long service life

• High concentration and dewatering efficiency, high solid content percentage in filter cakes

• Easy to maintain

• Low noise and less use of chemicals

Customizing Notes

Please provide throughput and material requirements.

Huaneng Jinhao manufactures water treatment equipment and domestic sewage treatment plant to global markets, with decades of experience, we can fabricate any water treatment equipment and machinery like industrial water decanter, water filtration equipment, sludge separation equipment, and the auxiliaries of water treatment equipment.

Index

solid liquid separation, industrial sludge treatment, sewage treatment