Belt Filter Press

Application

Our belt filter press continuously concentrates and filters a large amount of sludge. It is made of high strength materials, and features a large processing capacity, high dehydration efficiency and long service life, making it an ideal tool for use in commercial and municipal industries.

| Model | | | | | |

| Filter band width (mm) | 500 | 1000 | 1500 | 2000 | 3000 |

| Gravity filter area (m2) | 2.9 | 5.8 | 8.7 | 11.6 | 17.4 |

| Squeezing filter area (m2) | 2.4 | 4.8 | 7.2 | 9.6 | 14.4 |

| Speed of filter band (m/min) | 0.6-5.5 | 0.6-5.5 | 0.6-5.5 | 0.6-5.5 | 0.6-5.5 |

| Washing water pressure (Mpa) | >0.25 | >0.25 | >0.25 | >0.25 | >0.25 |

| Motor power (kw) | 1.1 | 1.1 | 2.2 | 2.2 | 3 |

| Shape size (mm) | 3400x800x1890 | 4400x1400x2190 | 4400x1900x2190 | 4400x1900x2190 | 4400x3400x2190 |

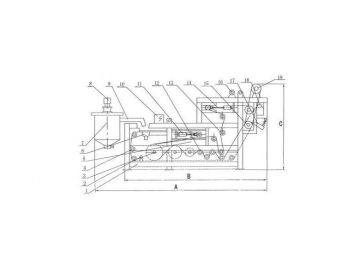

Design Details

The belt filter press is a continuously operating piece of solid-liquid separation equipment. After the sludge is flocculated, it undergoes gravity-dehydration, preloading dehydration and high-pressure dehydration. The filter cake then travels with the filter cloth until it reaches the discharge roller. (Our main dewatering pressure rollers are designed with holes.) A high-quality filter belt ensures a quick dewatering process during the filter filtration process, and our pressure rolls are arranged in such a way that they provide the most favorable pressure and shear force, thus significantly increasing the solid content percentage in the filter cakes and improving the dewatering efficiency. Our belt filter press uses two filter belts to perform press dehydration, with the gravity dewatering zone location before the normal pressure dewatering zone. This unique design improves the dehydration efficiency, reduces the use of chemicals, and lowers the energy consumption.

Main structures

Our device includes the tensioning system, baffle and scraping system, frame, roller group, filter belt, controller, transmission device, flushing system, guidance system, scraping-collecting device, bracket and water blocking device and electric control box.

1. Frame

2. Lower cleaning device

3. Lower pressure area

4. Lower guidance device

5. Wedge zone

6. Water tray

7. Sludge mixer

8. Mixer deceleration device

9. Feed zone

10. Machine control box

11. Lower tensioning device

12. High pressure zone

13. Upper guidance device

14. Upper tensioning device

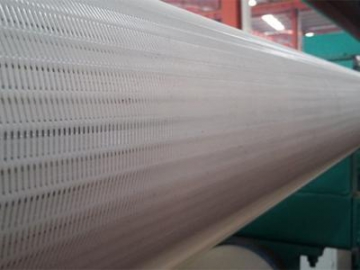

15. Filter belt

16. Upper cleaning device

17. Discharge tray

18. Upper scraper

19. Motor and decelerator

Filter press strainer

Filter press strainer Filter press control box

Filter press control box Filter Press

Filter Press Filter Press

Filter Press

Features

• Integrated equipment with automatic control provides continuous operation.

• Low energy consumption and long service life

• High concentration and dewatering efficiency, high solid content percentage in filter cakes

• Easy to maintain

• Low noise and less use of chemicals

• High cost-efficiency and reliability with a wide range of applications

Customizing Notes

Please provide throughput and material requirements.

Huaneng Jinhao manufactures water treatment equipment and domestic sewage treatment plant to global markets, with decades of experience, we can fabricate any water treatment equipment and machinery like industrial water decanter, water filtration equipment, sludge separation equipment, and the auxiliaries of water treatment equipment.

Index

solid liquid separation, industrial sludge treatment, sewage treatment