Chemical Dosing System (Injection with Diamine)

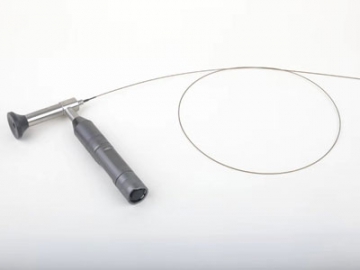

Hydrazine Injection System Parts

Hydrazine injection systems are chemical dosing systems that are comprised of a dosing tank, metering pump, electrical enclosure, liquid level gauge, safety valves, pulsation dampener, and pipes. Hydrazine injection systems are primarily used in water treatment operations where they inject hydrazine into the boiler system in order to prevent corrosion.

Automatic Control System Explained

Depamu hydrazine injection systems can operate in two modes: automatic and manual. The automatic control system manages sends flow rate, oxygen content, and opacity measurements to the PLC, host computer, or DCS which then tells the motor to adjust its speed and the pump to control its stroke.

Technical Specifications

Adjustable range of flow rate: 0~100%

Input Current Signal to VFD: 4~2mA

Feedback Current Signal: 4-2mA

Signals indicative of the operating status and faults of all metering pumps and mixers can be sent to the DCS or host computer which then controls the motor to stop or start. A total of three modes are available for the electrical enclosure: manual, semi-automatic, and automatic. Dosing tanks can be supplied in 316 stainless steel or 304 stainless steel.

Ready to buy a hydraulic diaphragm metering pump from us? Simply click on to fill out our Metering Pump Specifications Form and one of our professional design consultants will get back to you shortly.