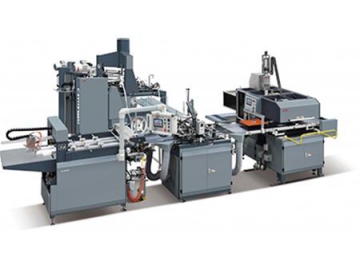

S600 Set Up Box making machine

S600 Set Up Box making machine is suitable for producing high-end rigid boxes through the whole streamline of automatic cardboard and paper delivery, four corners pasting, paper gluing, auto conveyance, positioning, pressing, automatic box drawing and catching, and wrapping, which can be done consecutively in one time to achieve high speed production.

Features

- Feeder part: Feeder transports a single sheet or gray cardboard each time automatically and accurately without deviation.

- Gluing part: The hot melt glue system can automatically heat, circulate, mix the glue and precisely control the required viscosity of the glue. After the gluing is completed, the gluing tank can be automatically cleaned.

- Corner pasting part: The glue part can automatically fold the imported gray cardboard and paste the four corners with hot melt glue, and then transport it to the specified position in conveyor.

- Spotter part: The hydropneumatic spotter device combines a precise photoelectric detection system to correctly position the gray cardboard box on glued wrap paper.

- Pressing part: The square pressing mold can press the box within its operating range, which can remove the air bubbles between the gray cardboard box and the sheet, keeping the contact surface level and smooth.

- Box forming part: Feeding, wrapping, ears folding and edge folding are completed at once.

- Control panel: The control panel with sensitive touch screen HMI system can freely switch the language between English and Chinese, which is convenient to operate.

- PLC: This machine adopts advanced PLC, which can precisely control every step of the automatic production of rigid boxes.

Parameters

| Parameters | S 600 | S 600A | |

| Sheet size (A×B) | A min. Amax. B min. B max. | 95mm 610mm 180mm 850mm | 95mm 610mm 180mm 850mm |

| Cardboard size (C×D ) | C D | 600mm 800mm | 600mm 800mm |

| Sheet thickness | 100-200g/m2 | 100-200g/m2 | |

| Cardboard thickness | T | 0.8-3mm | 0.8-3mm |

| Finished box size (W ×L×H ) | Wmin. Wmax. L min. L max. H min. H max. | 50mm 400mm 100mm 600mm 15mm 150mm | 50mm 400mm 100mm 600mm 15mm 150mm |

| Edge folding depth | R min. R max. | 7mm 35mm | 7mm 60mm |

| Fold ear depth | R min. R max. | 10mm 125mm | 10mm 125mm |

| Positioning accuracy | ± 0.5mm | ± 0.5mm | |

| Production speed | ≦35 sheets/min | ≦35 sheets/min | |

| Sheet stacking height | 300mm | 300mm | |

| Cardboard stacking height | 1000 mm | 1000 mm | |

| Electrical power | 16kw/380V/3 phases | 16kw/380V/3 phases | |

| Glue barrel capacity | 60L | 60L | |

| Air supply | 12L/min. 0.6Mpa | 12L/min. 0.6Mpa | |

| Machine weight | 6800kg | 6800kg | |

| Machine dimension | L6600×W 4100×H 3250mm | L6600×W 4100×H 3250mm |

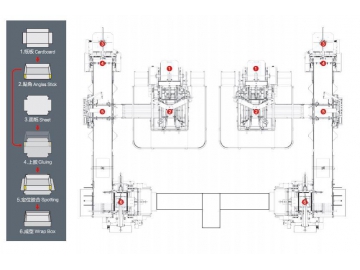

Process

Samples

Related products

Send Message

Most Recent

More

Other Products

Videos