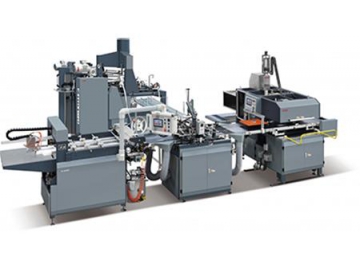

S460 Set Up Box making machine

Features

- Designed with a push-back paper feeding structure, the automatic paper feeder is pneumatically controlled and is simple in structure.

- The width between stacker and feeding table is adjusted concentrically in the center without operation error.

- The ultrasonic double paper tester is adopted to ensure only one sheet is fed each time.

- There are automatic circulation, mixing and gluing system for hot melt glue. And a glue viscometer can be optionally configured.

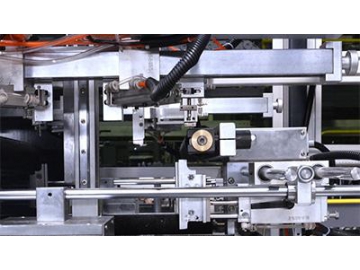

- Hot melt paper tape can realize automatic conveying and cutting, and can finish pasting four angles of the inner box of cardboard in one process.

- The vacuum suction fan under the conveyer belt can keep the paper from deviating.

- The inner box of glued sheet and cardboard is spotted correctly through the hydraulic rectifying device.

- Box forming part can continually wrap, fold ears and paper sides and form in one process.

- The machine is controlled by PLC system. The photoelectric tracking system enables the paper and cardboard being precisely positioned. And faults are displayed on the touch screen directly for convenient debugging.

- The machine can automatically diagnose the faults and alarm accordingly.

Parameters

| Parameters | S 460C | S 460 | |

| Sheet size (A×B) | A min. A max. B min. B max. | 95mm 610mm 180mm 850mm | 95mm 610mm 180mm 850mm |

| Cardboard size (C×D ) | C D | 600mm 800mm | 600mm 800mm |

| Sheet thickness | 100-200gsm | 100-200gsm | |

| Cardboard thickness | 0.8-3mm | 0.8-3mm | |

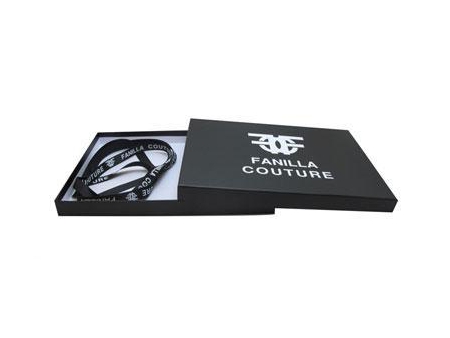

| Finished box size(W ×L×H ) | Min. Max. | 100×50×15mm 420×320×120mm | 100×50×15mm 420×320×120mm |

| Edge folding depth | R min. R max. | 10mm 100mm | 10mm 30mm |

| Fold ear depth | R min. R max. | 10mm 125mm | 10mm 125mm |

| Positioning accuracy | ± 0.3mm | ± 0.3mm | |

| Production speed | ≤20 sheets/min | ≤25 sheets/min | |

| Sheet stacking height | 300mm | 300mm | |

| Cardboard stacking height | 1000mm | 1000mm | |

| Electrical power | 10kw/380V/3phases | 10kw /380V/3phases | |

| Air supply | 10L/min 0.6Mpa | 10L/min 0.6Mpa | |

| Machine weight | 4500kg | 4500kg | |

| Machine dimension | L6800×W 4100×H 2800mm | L6800×W 4100×H 2800mm |

Related products

Send Message

Most Recent

More

Other Products

Videos