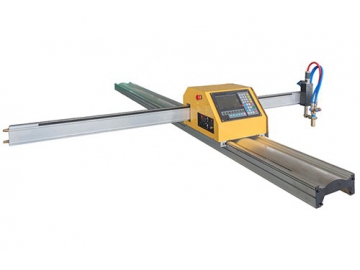

Flame Cutting Machine (Cutting Machine with HHO Generator)

- Kingkar 7000

- Kingkar 5000

- Kingkar 3000

Advantages of the Flame Cutting Machine

1. As an advanced production technology, the flame cutting machine can be safely and reliably operated.

2. The process flow is short and simple.

3. Both energy consumption and production costs are relatively low.

4. Easy to operate with high automation.

5. No environmental pollution.

| Model | KingKar3000 | KingKar5000 | KingKar7000 |

| Voltage (V) | Three phase 380V / 220V (50 to 60) HZ±10% | Three phase 380V / 220V (50 to 60) HZ±10% | Three phase 380V / 220V (50 to 60) HZ±10% |

| Rated capacity (KVA) | 9 | 15 | 22 |

| Working pressure (Mpa) | ≦ 0.2 | ≦ 0.2 | ≦ 0.2 |

| Relative humidity (%) | ≦ 90 | ≦ 90 | ≦ 90 |

| Rated gas output (L/H) | 3000±10% | 5000±10% | 7000±10% |

| Water consumption (L/H) | 1.6 | 2.7 | 3.8 |

| Max cutting thickness (mm) | 110 | 220 | 310 |

| Effective perforated thickness (mm) | 40 | 60 | 70 |

| Cooling Method | Air cooling | Air cooling | Air cooling |

| Insulation class | F | F | F |

| power protection level | IP2S | IP2S | IP2S |

| Flame temperature (℃) | 800-3200 adjustable | 800-3200 adjustable | 800-3200 adjustable |

| Working medium | Filtered water ordeionized water | Filtered water ordeionized water | Filtered water ordeionized water |

| Working Status | continuous | continuous | continuous |

| environment temperature(℃ ) | 0-40 | 0-40 | 0-40 |

| Dimension (L×W×H)(mm) | 1020×770×1270 | 1250×830×1720 | 1300×930×1820 |

| Weight(KG) | 293 | 567 | 653 |

Application of the Flame Cutting Machine

1. Our flame cutting machine can be used with carbon steel cutting machines in the construction, shipyard, and steel structure processing industries.

2. It is also applied to continuous cast slab cutting in steel plants.

3. The oxy-hydrogen flame cutting machine with cutting torch can be used as a manual cutting torch, semiautomatic cutting machine, shape cutting machine, or CNC cutting machine. We can customize CNC gas cutting equipment according to the customer's specific needs.

Cutting methods on the market today generally use oxygen and acetylene, propane, coke oven gas, or other gases, but our hydrogen gas and oxygen gas is an excellent replacement for industrial cutting. Through our research and development, we have seen hydrogen energy and water reduce the cost of cutting by 40% - 60% compared to traditional methods. In addition, our oxy-hydrogen equipment have a ten-year lifetime, which means that using flame cutting machine over a decade can save at least 3-5 times of the cost.

Working Process of Flame Cutting Machine

The principle of this cutting machine with HHO generator is based on the theory of electrolysis. The flame cutting machine consumes only water and electricity to turn water into pure hydrogen and oxygen gas, which can then be burned as an oxy-hydrogen flame. Oxy-hydrogen flame is a high temperature energy source, and our flame cutting machine can be used for precision cutting processing equipment in a safe, reliable, economical, and environmentally-friendly way.

Save Time and Money

Only water is needed for metal cutting, which is more affordable and available than acetylene, propane, or other fuels. The temperature of the oxy-hydrogen flame can reach 2,800 degrees Celsius for a highly concentrated flame. Compared with conventional fuels, oxy-hydrogen fuel saves more time and money.

Precision Cutting

The oxy-hydrogen flame has a concentrated and accurate fire point.

Safe and Pro-Environment

Because of its small density, oxy-hydrogen gas naturally rises instead of hovering on the ground at risk of explosion as other gaseous fumes are. We also design a trigger alert system to warn against unsafe conditions. Our oxy-hydrogen machine is then clean and won't harm the environment with pollutants.

Convenient and High-Tech

Crafted using the latest technologies, ourflame cutting machine is easy to operate and can cut steel with a thickness ranging from 50mm to 500mm.

Low Carbon Environment

The entire cutting process consumes about 4kW/H power and water; 1 liter of water can produce 1,860 liters of oxy-hydrogen gas. The oxy-hydrogen gas is very pure and has no color, taste, harmful effects, CO, or CO2.

| Steel Thickness | Acetylene | Kingkar Oxy-hydrogen Generator | Efficiency | |||||

| Consumption (NL/min) | Cost ($NT) | Time (Min.'Sec.)" | Electricity (Kwh) | Coolant (cc) | Cost ($NT) | Time (Min.'Sec.) " | ||

| 6mm | 4 | 1.237 | 2.00" | 0.09 | 35 | 0.89 | 1.52" | 8 seconds faster |

| 12mm | 9 | 3.253 | 2.20" | 0.155 | 38 | 1.16 | 2.16" | 4 seconds faster |

| 20mm | 9 | 4.064 | 2.55" | 0.158 | 38 | 1.17 | 2 .30" | 25 seconds faster |

| 50mm | 13 | 7.88 | 3.55" | 0.221 | 55 | 1.66 | 3.38" | 17 seconds faster |