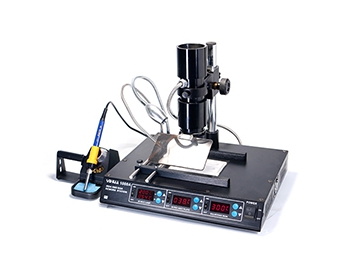

Precision BGA Rework System

Features

1. No need of nozzles, no airflow during re-flow process.

2. Use non-contact infrared temperature sensor to measure temperature real-timely, and achieve closed loop control of temperature during rework process, especially suitable for lead free process.

3. By reflecting foil to reduce thermal transmission to adjacent components.

4. Camera of BGA Rework System can be used to monitor the re-flow process.

5. No airflow during the process of BGA re-balling, and the success ratio of BGA re-balling can almost be up to 100%.

Specifications

IR Infrared Rework System

| Model | IR2005 |

| General power | 1600Watt(max) |

| Power of bottom heater | 400W*2=800Watt(Dark infrared heating plate) |

| Power of top heater | 180W*4=720Watt (Infrared heating tube, wavelength about 2-8μm) |

| Size of top heater | 60*60mm |

| Size of bottom heater | 135*250mm |

| Range of top heater | 20-60mm(X, Y direction both adjustable) |

| Vacuum pump | 12V/300mA, 0.05Mpa(max) |

| Top cooling fan | 12V/300mA, 15CFM |

| Laser alignment tube | 3V/30mA |

| Movable motor | 24V DC/100mA |

| Movable arm range | 93mm |

| Max PCB size | 300mm*300mm |

| LCD window | 65.7*23.5mm 16*2 characters |

| Soldering station | Intelligent digital lead free soldering station |

| Soldering power | 60Watt |

| Communication | RS-232C(connect with PC) |

| Infrared temperature sensor | 0-300℃(Testing range) |

| External K-type sensor | Optional |

| Weight | About 13kg |

PL Precision Placement System of BGA Rework System

| Model | PL2005 |

| Power | About 15Watt |

| Camera | 22*10 times magnifying; 12V/300mA Horizontal resolution: 480 lines; PAL format |

| Lens size | 40mm*40mm |

| Size of BGA to be aligned | 40mm*40mm |

| Vacuum pump | 12V/600mA 0.05Mpa(max) |

| Camera output signal | Video Signal |

| Weight | 22kg |

RPC Reflow Soldering Process Camera

| Model | RPC2005 |

| Power | About 15Watt |

| Camera | 22*10 times magnifying; 12V/300mA; Horizontal resolution: 480 lines; PAL format |

Main parts of BGA Rework System

1. Infrared heating system

Open-type dark infrared heating, non-contact infrared temperature sensor monitors the surface temperature changes of BGA, realize closed-loop control, ensure precise temperature technical window and even heat distribution.

Dark infrared heating technology with 2-8μm long wave can minimize temperature differences to avoid damages resulted from long dipping, cold soldering and overheating.

2. Heating system of BGA Rework System

Bottom dark infrared ceramic heating plate, 800W power; PCB can be preheated evenly and protected from being distorted and damaged. The top heater uses 720W dark infrared heating tube, heating area can be adjusted according to sizes of BGA. When process is over, vacuum will generate automatically to pick up BGA components and return to original position.

3. Soldering Station of BGA Rework System

Intelligent digital soldering station uses high frequency current heating method. It is easy to clean the soldering pad.

4. Nozzles, clamps of BGA Rework System

Special PCBs or PCBs with sockets, connectors can be fixed by the clamps of different lengths.

The nozzles can be selected as per actual sizes of BGA/CSP.

Operating Diagram

Features

1. IR2015 Infrared reflow soldering section of BGA rework system

Infrared temperature sensor monitors BGA surface temperature directly, realize close loop control, ensure precise temperature technical window and even heat distribution.

2. PL2015 Precise aligning and placing system of BGA rework system

Visible double-colors optical lens alignment, overlap alignment between solder ball and soldering pad is scientific and accurate; easy control, and pick-up and placement.

3. RPC2015 Reflow Camera of BGA rework system

The melting process of BGA solder ball can be observed from different angles, provides critical information to get accurate and reliable process curve.

4. IRsoft Software of BGA rework system

The whole process can be recorded, controlled and analyzed and then generate curve diagram by connecting to PC, can meet the demands of modern electronic industry.

Specifications

IR Infrared Rework System

| Model | IR2015 |

| General power | 2800Watt(max) |

| Power of bottom heater | 500W*4=2000Watt or |

| 400W*4=1600Watt(High Infrared heating tube/ Dark Infrared heater optional) | |

| Power of top heater | 180W*4=720Watt (Infrared heating tube, wavelength about 2-8μm) |

| Size of top heater | 60*60mm |

| Size of bottom heater | 267*280mm |

| Range of top heater | 20-60mm(X, Y direction both adjustable) |

| Vacuum pump | 12V/300mA, 0.05Mpa(max) |

| Top cooling fan | 12V/300mA, 15CFM |

| Laser alignment tube | 3V/30mA |

| Movable motor | 24V DC/100mA |

| Movable arm range | 93mm |

| Max PCB size | 420mm*500mm |

| LCD window | 65.7*23.5mm 16*2 characters |

| Communication | RS-232C(connect with PC) |

| Infrared temperature sensor | 0-300℃(Testing Range) |

| External K-type sensor | Optional |

PL Precision Placement System

| Model | PL2015 |

| Power | About 15Watt |

| Camera | 22*10 times magnifying; 12V/300Ma Horizontal resolution: 480 lines; PAL format |

| Lens size | 60mm*60mm |

| Size of BGA to be aligned | 60mm*60mm |

| Vacuum pump | 12V/600mA 0.05Mpa(max) |

| Camera output signal | Video Signal |

| Weight | 22kg |

RPC Reflow Soldering Process Camera of BGA rework system

| Model | RPC2015 |

| Power | About 15Watt |

| Camera | 22*10 times magnifying; 12V/300mA; Horizontal resolution: 480 lines; PAL format |

Main Parts of BGA Rework System

Infrared heating system of BGA rework system

Open-type dark infrared heating, non-contact infrared temperature sensor monitors the surface temperature changes of BGA, realize closed-loop control, ensure precise temperature technical window and even heat distribution.

Top heater of BGA rework system

The top heater uses 2-8μm long wave infrared heating tube, 720W, heating area can be adjusted according to sizes of BGA, protect adjacent components from being heated. No need of nozzles, save cost.

Bottom heater of BGA rework system

The bottom heater uses 4 sets of dark infrared heating plates, with a large power 1600W. Larger PCBs can be placed and heated evenly, avoid deformation and damage.

Optical lens alignment of BGA rework system

The PL part uses optical lens to align components. Red top light, white bottom light, brightness is adjustable. Light source reflected by lens to ensure BGA solder ball and PCB solder pad in line with each other and even.

The solder ball and pad will show clearly in the monitor through the camera of PL part. By adjusting the X, Y axis fine knob and component control knob, solder ball which displays in red and solder pad which displays in white can overlap completely.

Alignment adjustment of BGA rework system

The most precise alignment can realize by fine adjustment of X, Y, Z angles.

Components aligning knob can make BGA 360° rotating.

PCB fixing of BGA rework system

The flexible PCB supporting rod can fix PCB effectively, absorb the expansion force resulted from heating or cooling, prevent the PCB from distortion.

Special PCB can be fixed by different clamps. The supporting rod can be used for the bottom of large PCB to avoid distortion.

Features

1. BGA2105 rework system uses excellent heating materials to control the process of BGA soldering and de-soldering process accurately.

2. Large power brushless DC fan, temperature controlled by closed loop sensor and micro computer zero triggering, generate large volume of hot air.

3. Various types of titanium nozzles available, easy replacement.

4. Program can be set to control top and bottom hot air temperature, precise and even.

5. Powerful fan cools bottom heating area rapidly.

6. BsolderingSOFT available, easy operation.

Specifications

| General power | 3500W(max) |

| Power supply | 220V AC, 50/60Hz |

| Power of top heater | 700Watt |

| Power of bottom pre-heater | 400Watt*4=1600Watt(Infrared heater) |

| Power of bottom heater | 700Watt |

| Speed of side cooling fan | ≤3.5 m3/min |

| Temperature range(Hot air) | 500℃(Max) |

| Temperature range(Preheating) | 500℃(Max) |

| Bottom preheating area | 330*360mm |

| Max PCB size | 330*360mm |

| External K-type sensor | 3pcs |

| Communication | RS-232C(connect with PC) |

| Net weight | About 23.5kg |

| Dimensions | 610(L)*580(W)*520(H)mm |

Nozzles of BGA rework system

| Part number | Size (mm) | |

| N0707 | 7*7 | |

| N0909 | 9*9 | |

| N1313 | 13*13 | |

| N1515 | 15*15 |

| Part number | Size (mm) | Part number | Size (mm) | |

| N1818 | 18*18 | N2222 | 22*22 | |

| N2424 | 24*24 | N2626 | 26*26 | |

| N2828 | 28*28 | N3030 | 30*30 | |

| N3232 | 32*32 | N3535 | 35*35 | |

| N3737 | 37*37 | N3939 | 39*39 | |

| N4444 | 44*44 | N4949 | 49*49 | |

| N5252 | 52*52 |

Features

1. High automatization, the de-soldering, pick-up and placement of chips can be finished by one button, easy operation.

2. Use large power brushless DC fan, closed loop of sensor and micro-computer zero triggering, can generate large volume of hot air. No need for external air supply, easy operation.

3. Seven temperature areas, suitable for reflex BGA, multilayer BGA and metal shielding case.

4. Integrative design, combines heating system and alignment system together.

5. Visible double-colors optical lens alignment, controlled by rocker, clear and precise.

6. Large power fan, speed adjustable, cool bottom heating area quickly.

7. BsolderingSOFT interface, with operation right limitation and profile analysis function available. Can analyze preheating speed, peak temperature, temperature preserving time and cooling rate effectively.

8. Various types of titanium alloy hot air nozzles available, easy replacement.

Specifications

| Power supply | 220V AC, 50Hz, 5KW |

| Max PCB size | 600*500mm |

| Min IC size | 2*2mm |

| Max IC size | 60*60mm |

| Size of bottom heater | 550*450mm |

| LCD window | 100*75mm 16*2 characters |

| Mounting Accuracy | ±0.025mm |

| Hot air temperature | 500℃(Max) |

| Bottom preheating temperature | 500℃(Max) |

| Power of top heater | 800Watt |

| Power of bottom heater | 800Watt |

| Power of bottom infrared pre-heater | 3200Watt |

| Speed of side cooling fan | ≤ 3.5m3 /min |

| Camera | 12V/300mA 22*10 times magnifying Horizontal resolution: 480 lines PAL format |

| Outside K-type sensor | 5 pcs |

| Communication | RS-232C(connect with PC) |

| Dimensions | 1150(L)*800(W)*800(H)mm |

| Weight | About 120kg |

Main Parts of BGA Rework System

Heating System of BGA rework system

800W hot air power for top and bottom heaters, airflow is stepless. The temperature of main heating area can rise quickly. Heat distributes evenly, decrease the vertical temperature difference between chip surface and soldering joint, shorten the whole process.

Main heater of BGA rework system: top hot air bottom hot air

Seven temperature areas, air volume, temperature and heating time of both top and bottom heaters can be adjusted as per requirements. Accurate temperature and even heat distribution can ensure the precision and flexibility of the process.

External 5 K-type sensors, can monitor temperature of PCB and BGA accurately.

Pick-up chips of BGA rework system

Vacuum will generate automatically and pick up BGA chips when the process is finished, then the vacuum will return to original position.

Features

1. BGA rework system can ensure even heat distribution and right peak temperature and realize reliable lead-free soldering. Uses closed loop sensor and hot air top heater, sectional hot air for BGA, infrared heating part for complete PCB to prevent PCB from being deformation.

2. 60*60MM optical alignment lens, alignment of large BGA can still show clearly. Align glass is controlled by motor, and small plate for chips is placed above the glass. Special supporting rods can be placed in frame structure of PCB. The bottom supporting rods of BGA rework system are connected with landscape orientation rods to make sure accordance when place PCB. Fine adjustment of X, Y, Z, θ controlled by rocker, linear precision orbit and precision silk pole. Uses motor to control rough and fine adjustment.

3. Except using manual fine adjustment of X, Y, θ in chip fine alignment, Bsoldering BGA2120 can automatically control the pick-up, placement and de-soldering of chips, movement of glass and heater, reflow control etc. which is unique in lead-fee rework systems.

Specifications

| General power | 2200W(max) |

| Power supply | 220V/230V AC, 50/60HZ |

| Top heating power | 700W |

| Bottom heating power | 700W |

| Bottom preheating power | 800W |

| Air speed of side cooling fan | ≤3.5m3/min |

| Hot air temperature | 500℃(MAX) |

| Hot air temperature range | 500℃(MAX) |

| Bottom preheating size | 300*300mm |

| Max PCB size | 300*300mm |

| Chip size | 2*2-60*60mm |

| Placement precision | ±0.025mm |

| Camera | 12V/300mA 22*10 times magnifying; Horizontal resolution: 480lines PAL format |

| LED Light | Bottom white LED and top red LED(brightness adjustable) |

| LCD window | 100*75(mm) 16*2 characters |

| Communication | RS-232C(Connect with PC) |

| Vacuum | 12V/300mA, 0.05Mpa(MAX) |

| External K type sensor | 5PCS |

| Net weight | 50kg |

| Dimension of BGA rework system | 600(L)*600(W)*500(H)mm |